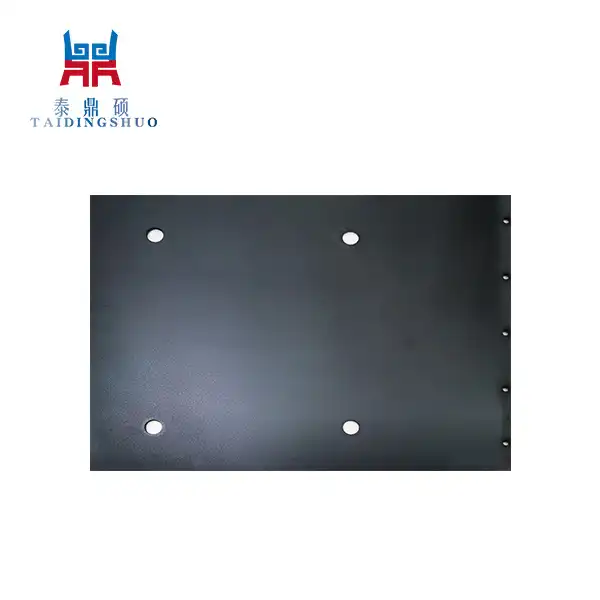

Product Description

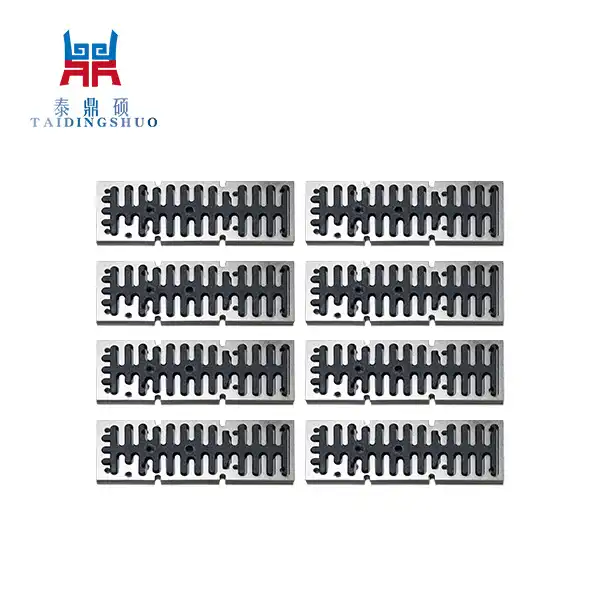

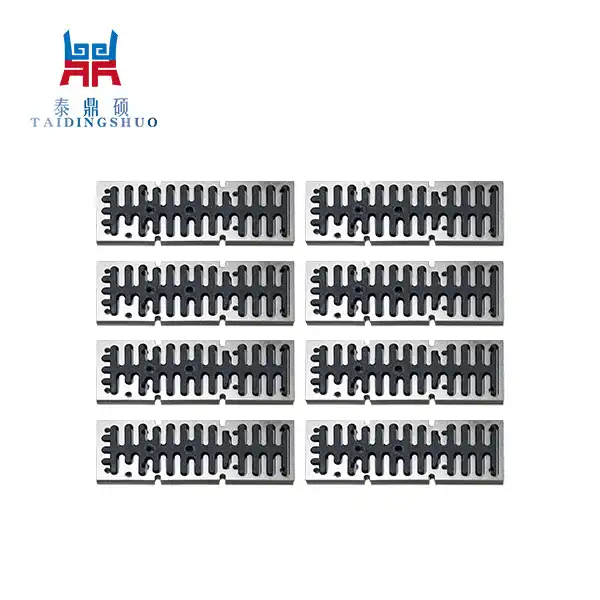

Our Iridium-Tantalum coated titanium anode is fastidiously created to satisfy the most noteworthy guidelines of sturdiness, proficiency, and unwavering quality. Built from premium-grade titanium substrate and coated with a double layer of iridium and tantalum, this anode offers remarkable consumption obstruction and electrochemical execution in a large number of utilizations.

Product Standards:

- Compliant with ASTM B265/B338 standards

- Customizable to meet specific industry requirements

Basic Parameters:

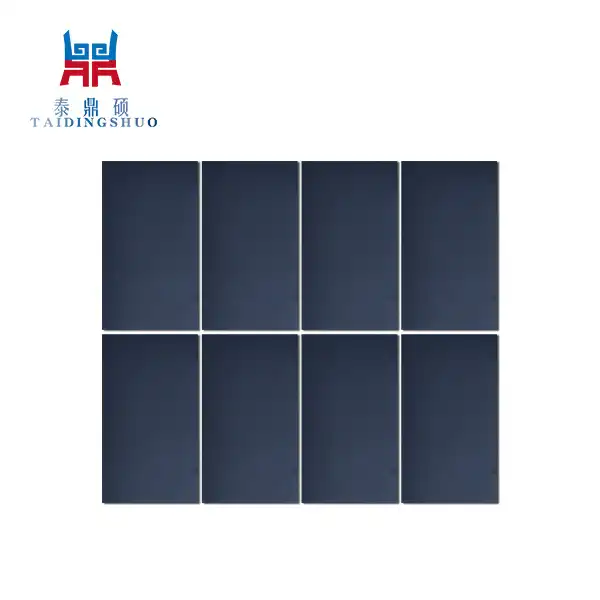

- Material for Substrate: Titanium

- Covering Material: Iridium-Tantalum

- Covering Thickness: 10-20 microns

- Maximum Operating Temperature and pH Scale: 80°C,0–14

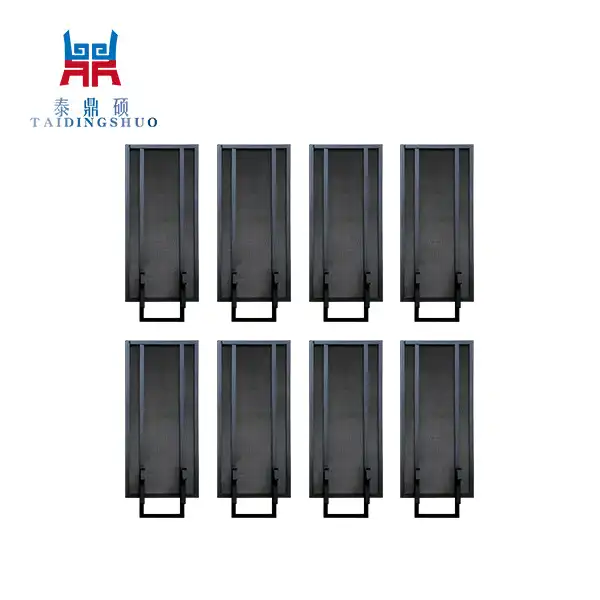

Product Attributes:

- Superior corrosion resistance

- High conductivity

- Long service life

- Low maintenance requirements

- Excellent electrochemical performance

Product Functions:

A number of electrochemical processes, such as electroplating, water treatment, and cathodic protection systems, rely heavily on our titanium anode coated with iridium-tantalum. It works with productive electron move and guarantees steady execution even in brutal working conditions.

Features:

- Two-layer covering to increase robustness

- homogeneous and steady distribution of current

- broad compatibility throughout a pH range

- Ideal for settings that are both acidic and alkaline

- resistance to corrosion caused by chloride

Advantages and Highlights:

- Extended service life compared to conventional anodes

- Reduced downtime and maintenance costs

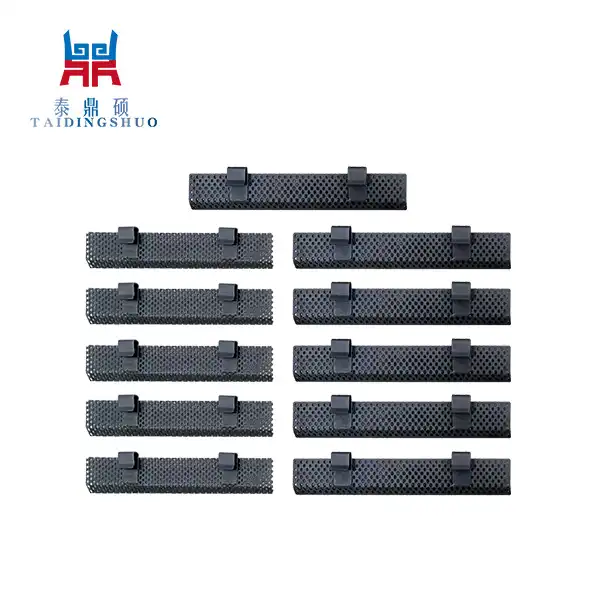

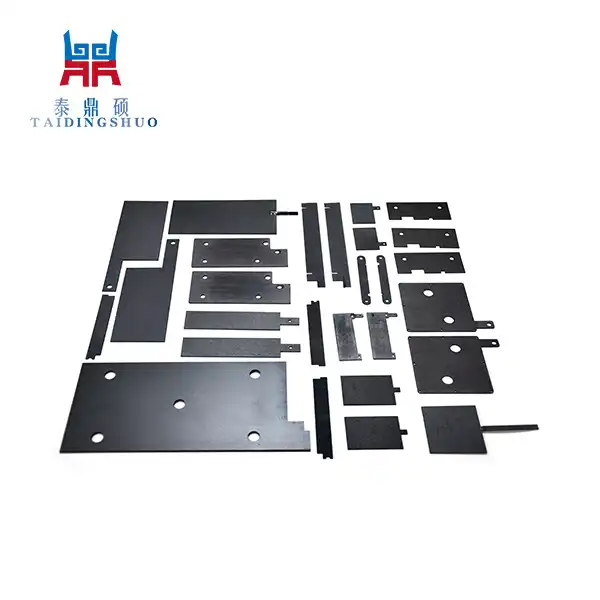

- Customizable designs to fit specific applications

- Exceptional performance in demanding conditions

- Cost-effective solution for long-term use

Application Areas:

- Electroplating Industry: In electroplating, these anodes are used to deposit metal coatings onto substrates, enhancing surface properties like conductivity, corrosion resistance, and aesthetics. They satisfy the quality guidelines requested by ventures going from gadgets to car by guaranteeing uniform affidavit of metals like gold, silver, nickel, and chrome.

- Chlor-Alkali Production:These anodes are essential components of electrolysis cells used to produce hydrogen, sodium hydroxide, and chlorine gas in the chlor-alkali industry. They empower the electrochemical decomposition of brackish water (sodium chloride arrangement), working with the development of fundamental chemicals used in different industrial processes.

- Metal Finishing: iridium tantalum titanium anode are employed in metal finishing processes, including electroforming, anodizing, and electrochemical machining. They assist with accomplishing wanted surface qualities, like superior erosion obstruction, wear opposition, and attachment, in applications like aviation parts, clinical gadgets, and shopper hardware.

- Chemical Processing: These anodes are integral to various chemical processing applications, where they facilitate electrochemical reactions for the synthesis of specialty chemicals, pharmaceuticals, and fine materials. Their corrosion resistance and stability make them suitable for use in aggressive chemical environments, ensuring reliable performance and product quality.

- Water Treatment: In water treatment applications, anodization of titanium are utilized in electrochemical processes for disinfection, oxidation, and removal of contaminants from water sources. They help in the expulsion of contaminations, pathogens, and natural mixtures, adding to the creation of protected and consumable water for civil and modern use.

- Cathodic Protection Systems: These anodes are employed in cathodic protection systems to prevent corrosion of metal structures such as pipelines, storage tanks, and offshore platforms. By generating a protective electrical current, they inhibit the oxidation of metal surfaces, extending the lifespan and integrity of critical infrastructure components.

OEM Services:

We offer thorough OEM administrations to meet the interesting prerequisites of our clients. Our accomplished designing group teams up intimately with clients to foster custom fitted arrangements that line up with their particulars and execution targets.

Certifications:

FAQs:

-

What is the typical lifespan of your Iridium-Tantalum coated titanium anode?

- Our anodes can last several years under normal operating conditions, with proper maintenance.

-

Can you customize the dimensions and configurations of the anode?

- Yes, We can change the anode's size, shape, and different boundaries to suit your specific prerequisites.

-

Is the anode suitable for use in highly corrosive environments?

- Absolutely. The iridium-tantalum coating provides excellent resistance to corrosion, even in aggressive media.

Material Properties:

- Iridium: Known for its exceptional corrosion resistance and catalytic properties.

- Tantalum: Offers high chemical security and protection from consumption, especially in acidic conditions.

Tai Ding Shuo Industrial Co., Ltd.:

As a professional manufacturer and supplier of the anodes, Tai Ding Shuo Industrial Co., Ltd. is committed to delivering top-quality products and services to our global clientele. We provide various standard and customized certifications, complete test reports, and support OEM requirements. With our fast delivery, secure packaging, and reliable support, we ensure a seamless experience for our customers. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.

In conclusion, our Iridium-Tantalum coated titanium anode stands as a testament to our dedication to innovation, quality, and customer satisfaction. Whether you're in the electroplating industry, chemical processing, or water treatment, our anode offers the performance and reliability you can trust.