Product Description

Our Titanium Anode for Hydrogen Peroxide Arrangement by Electrolysis is carefully created to meet the requesting needs of modern electrolysis processes. It fills in as a significant part in the effective creation of hydrogen peroxide through electrolysis, offering unmatched execution and toughness.

Product Standards:

-

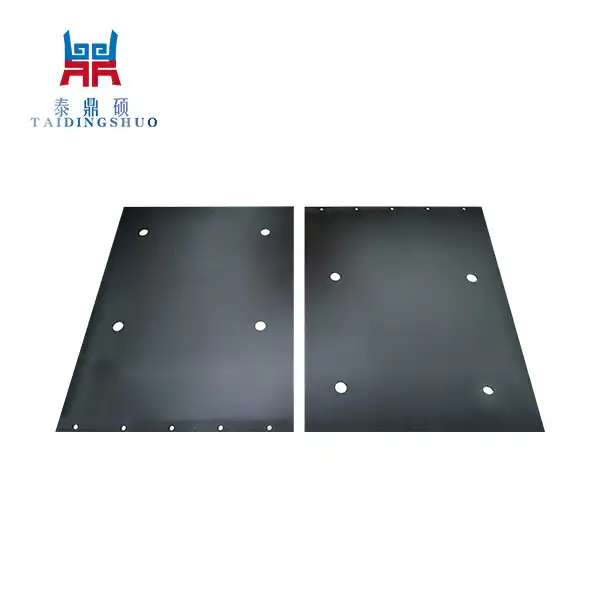

Material: Titanium Grade 1 or Grade 2

-

Covering: IrO2 (Iridium Oxide) or RuO2 (Ruthenium Oxide)

-

Aspect: Adaptable to meet the needs of the customer

-

Connector: Bolt, Brace, or Spine

-

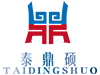

Plan: Cross section, Plate, or Bar

Basic Parameters:

| Parameter | Value |

|---|---|

| Coating Thickness | 5-10 microns |

| Working Temperature | Up to 80°C |

| Current Density | Up to 3000 A/m2 |

| pH Range | 1-13 |

| Electrolyte | Hydrochloric Acid, Sulfuric Acid, or Salt Solutions |

| Lifetime | 3-5 years |

Product Attributes:

- Anti-corrosion properties: extremely corrosion-resistant, ensuring longevity in harsh chemical environments.

High productivity: Improved plan considers most extreme current thickness and proficiency in hydrogen peroxide creation.

Customizable: Customized to explicit application prerequisites, guaranteeing ideal execution.

Proven results: Efforts to minimize downtime and expenses associated with maintenance are achieved through consistent and stable operation.

Product Functions:

Our titanium anode manufacturer works with the electrolytic creation of hydrogen peroxide, empowering enterprises to productively produce this fundamental synthetic compound for different applications including blanching, water treatment, and substance amalgamation.Here are the vital elements of a product producer:

Material Determination: For the production of anodes, a manufacturer chooses materials made of the product or titanium alloy of high quality. They ensure that the material meets the required standards for conductivity, strength, and resistance to corrosion.

Plan and Designing: The products are created and engineered by manufacturers in accordance with the application's specific requirements. To achieve optimal performance, this includes figuring out the anode's shape, size, and configuration.

Producing Cycle: Makers utilize specific gear and procedures to create the products. Cutting, shaping, welding, and coating the product material may all be part of this procedure to achieve the desired results.

Control of Quality: Through stringent quality control procedures, a manufacturer guarantees the quality of the products. This incorporates testing the anodes for consumption opposition, electrical conductivity, and in general execution before they are delivered to the market.

Customization: To cater to the distinctive requirements of their customers, manufacturers provide customization options. This might entail making anodes in various sizes, shapes, and configurations to suit particular applications.

Technical Assistance: Customers receive technical assistance from manufacturers for the selection, installation, and upkeep of the products. They offer ability and direction to guarantee the anodes perform ideally in their expected applications.

Management of the Supply Chain: Makers deal with the store network to guarantee a consistent stockpile of unrefined substances and parts for anode creation. They also make sure that finished goods are delivered to customers on time.

Development and Research: Makers put resources into innovative work to work on the presentation and proficiency of the products. They investigate new advancements and materials to improve the capacities of their items.

Certification and compliance: The compliance of a manufacturer's the products with industry standards and regulations is ensured. In order to guarantee the safety and quality of their products, they obtain approvals and certifications.

Service to Customers: To address any questions or concerns regarding titanium hydrogen peroxide anodes, manufacturers offer excellent customer service. By providing dependable products and support, they aim to maintain long-term customer relationships.

Features:

-

Improved solidness

-

Superb conductivity

-

Uniform covering conveyance

-

Low energy utilization

-

Simple establishment and upkeep

Advantages and Highlights:

-

superior resistance to corrosion in comparison to conventional anode materials.

-

Longer help life, decreasing substitution recurrence and related costs.

-

The design's adaptability ensures compatibility with a variety of electrolysis systems.

-

Productivity increases and expenses are reduced when efficiency is high.

Application Areas:

-

Titanium anode manufacturer primarily use their products in the following fields:

-

Electroplating

-

Water Treatment

-

Industry of Chloroalkali

-

Synthesis by Electrochemistry

-

Cathodic Security

-

Electrolytic Recuperation

-

Applications for electroplasma

-

Sensors by Electrochemistry

-

Hydrometallurgy

-

Sustainable power

OEM Services:

We provide comprehensive OEM services and custom solutions tailored to our clients' specific needs. From plan to creation, our accomplished group guarantees the best norms are met.

Certifications:

FAQs:

Q: What is the generally anticipated life expectancy of your products?

A: Depending on operating conditions and routine maintenance, our the products typically lasts three to five years.

Q: Could the elements of the anode at any point be modified?

A: Yes, we provide options for customization to meet the specific needs of each application.

Properties and Details of the Material:

Titanium Grade 1 or Grade 2 is chosen because it is biocompatible and resistant to corrosion. The covering of IrO2 or RuO2 upgrades conductivity and gives extra assurance against erosion, guaranteeing long haul dependability in electrolytic conditions.

Tai Ding Shuo Industrial Co., Ltd.:

As a main producer and provider of Titanium Anode for Hydrogen Peroxide Planning by Electrolysis, Tai Ding Shuo Modern Co., Ltd. is focused on conveying predominant items and excellent assistance. We give different norm and modified confirmations, complete test reports, and backing OEM prerequisites. Our quick conveyance, secure bundling, and devoted client care guarantee a consistent encounter for our clients around the world. Please contact us at fujianguo@shelllaiqi.com with any inquiries or orders.