Product Description

As a leading manufacturer and supplier in the field of electrolysis technology, Tai Ding Shuo Industrial Co., Ltd. proudly presents its cutting-edge Titanium Anode tailored specifically for hydrogen production through the electrolysis of seawater. This innovative product is meticulously designed to meet the stringent demands of professional buyers and global dealers seeking high-quality solutions for hydrogen generation.

Basic Product Details:

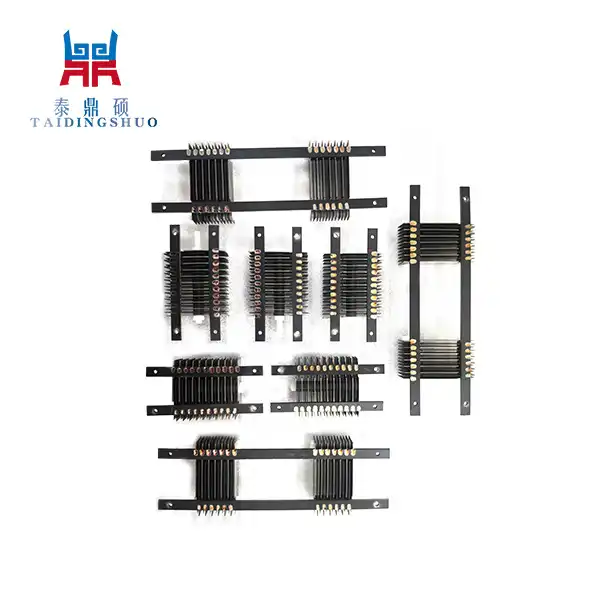

Our Titanium Anode for hydrogen production boasts exceptional durability and efficiency, making it ideal for various industrial applications. Crafted from premium-grade titanium material, this anode is engineered to withstand the corrosive environment of seawater electrolysis, ensuring long-term performance and reliability. With fastidious tender loving care, our group of specialists guarantees that every anode satisfies the most noteworthy guidelines of value and accuracy.

Product Standards:

- Material: Titanium

- Coating: Ruthenium-Iridium Oxide (Ru-IrO2)

- Dimensions: Customizable based on client requirements

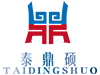

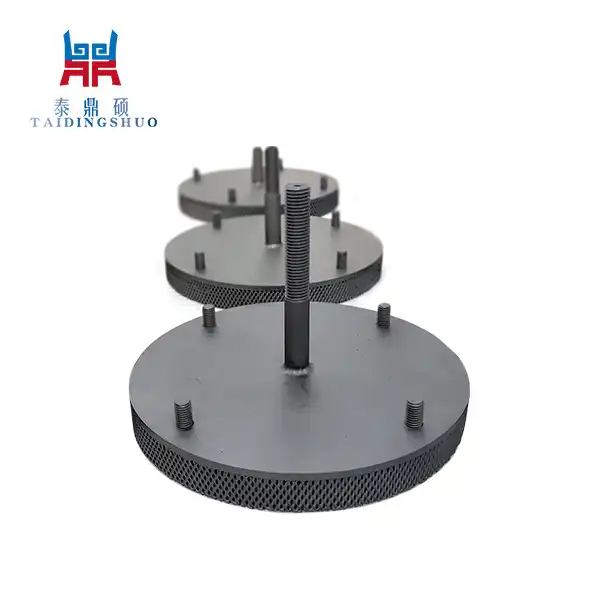

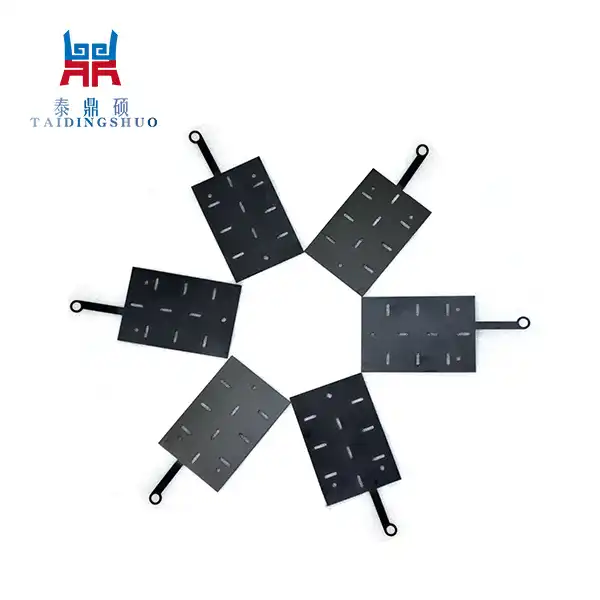

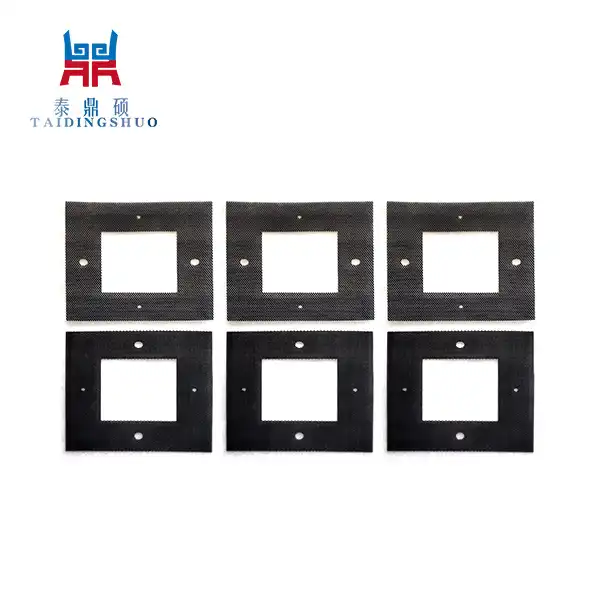

- Electrode Shape: Sheet, Mesh, or Rod

- Electrolyte: Seawater

Basic Parameters:

| Parameter | Value |

|---|---|

| Working Temperature | Ambient to 80°C |

| Current Density | Up to 2000 A/m² |

| pH Range | 0-14 (Suitable for alkaline conditions) |

| Coating Thickness | 5-10 microns |

| Expected Lifespan | 5-10 years |

Product Attributes:

- Corrosion Resistance: Superior resistance to corrosion in seawater environments, ensuring prolonged lifespan.

- High Efficiency: Optimized design for enhanced electrolysis efficiency, leading to increased hydrogen production.

- Customizable: Available in various sizes and configurations to accommodate diverse industrial requirements.

- Eco-Friendly: Enables clean and sustainable hydrogen production without greenhouse gas emissions.

- Low Maintenance: Requires minimal maintenance, reducing operational costs and downtime.

Product Functions:

Through the following reactions, the salt water titanium anodizing makes it easier for seawater to be electrolyzed to produce hydrogen gas:

- At the anode: 2H2O(l) → O2(g) + 4H⁺(aq) + 4e⁻

- At the cathode: 4H⁺(aq) + 4e⁻ → 2H2(g)

Features:

- Constructive Stability: made of high-quality titanium and coated with a long-lasting Ru-IrO2 material for long-lasting performance.

- High Catalytic Activity: The Ru-IrO2 coating provides excellent catalytic activity, ensuring efficient hydrogen evolution.

- Versatile Application: Suitable for various electrolysis processes, including seawater electrolysis for hydrogen production.

- Easy Installation: Designed for hassle-free installation and integration into existing electrolysis systems.

- Safe Operation: Manufactured adhering to strict safety standards to ensure safe operation in industrial settings.

Advantages and Highlights:

- Superior Durability: Resistant to corrosion and degradation, ensuring prolonged lifespan and consistent performance.

- Enhanced Efficiency: Optimized design and coating ensure high electrolysis efficiency, leading to increased hydrogen yield.

- Customization Options: Tailored solutions available to meet specific client requirements and application needs.

- Environmental Sustainability: Facilitates clean hydrogen production, contributing to a greener and more sustainable future.

- Reliable Support: Backed by comprehensive technical support and after-sales service to address any queries or issues promptly.

Application Areas:

- Chemical Industry: Hydrogen serves as a crucial raw material in various chemical processes, including ammonia production and hydrocracking.

- Energy Sector: Salt water titanium anodizing is utilized as a clean fuel for fuel cells and combustion engines, offering a sustainable alternative to fossil fuels.

- Metal Processing: Hydrogen is used in metal refining processes, such as hydrogenation and desulfurization.

- Electronics Industry: Titanium Electrode for Seawater Electrolysis is employed in the production of semiconductors and flat-panel displays.

OEM Services:

We offer OEM services to meet the unique requirements of our clients, including customized anode designs, branding, and packaging options.

Certifications:

FAQs:

-

What is the expected lifespan of the Titanium Anode?

- The expected lifespan ranges from 5 to 10 years, depending on operating conditions and maintenance practices.

-

Can the anode be customized to fit specific electrolysis systems?

- Yes, we offer customization options to ensure compatibility with various electrolysis setups and requirements.

-

Is technical support available for installation and troubleshooting?

- Yes, we provide comprehensive technical support to assist with installation, operation, and maintenance queries.

-

What are the environmental benefits of using hydrogen as a fuel?

- Hydrogen is a clean and sustainable fuel source, emitting only water vapor when combusted, thus reducing greenhouse gas emissions and mitigating environmental impact.

About Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a professional manufacturer and supplier specializing in advanced electrolysis technology solutions. With a commitment to quality, innovation, and customer satisfaction, we provide a comprehensive range of products, including Titanium Electrode for Seawater Electrolysis for various industrial applications. Our products adhere to strict quality standards and are supported by complete test reports and certifications. We offer OEM services, fast delivery, and reliable technical support to meet the diverse needs of our global clientele. For inquiries or to explore our product solutions for hydrogen production, please contact us at fujianguo@shelllaiqi.com.