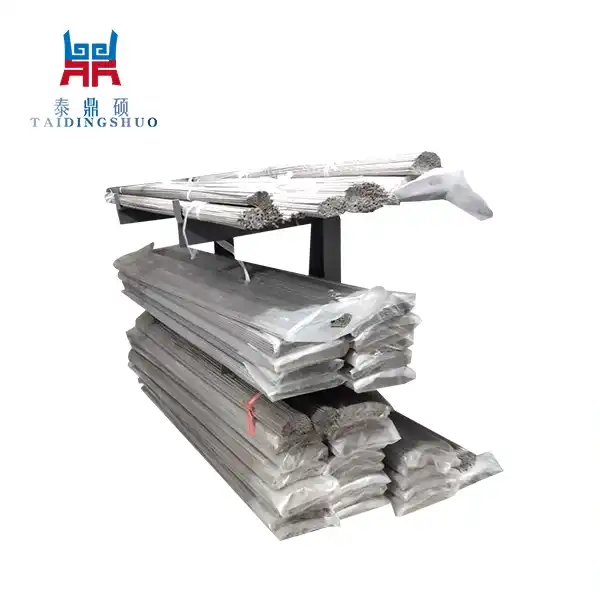

Product Description

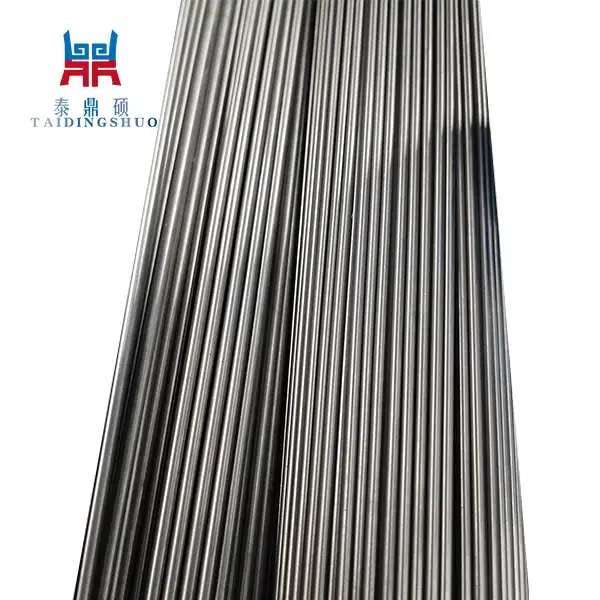

Titanium mig welding wire is a high-quality welding material manufactured by Tai Ding Shuo Industrial Co., Ltd., a professional manufacturer and supplier of titanium products. This welding wire is meticulously crafted to meet the demanding standards of professional welders and industries requiring precision welding.

Product Standards:

- ASTM B348

- ASTM B863

- AWS A5.16

- ISO 5832-2

- DIN 17862

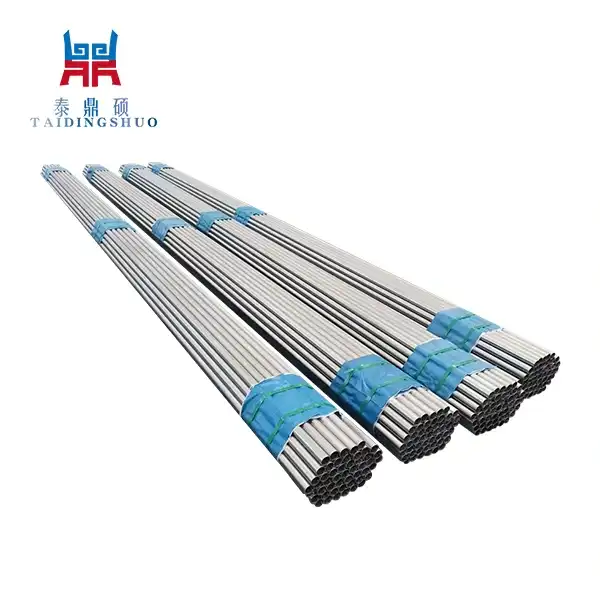

Basic Parameters:

| Parameter | Value |

|---|---|

| Grade | Gr1 (CP Titanium) |

| Diameter | 0.8mm - 4.0mm (Customizable) |

| Length | 1000mm - 3000mm (Customizable) |

| Tensile Strength | 240 MPa |

| Yield Strength | 170 MPa |

| Elongation at Break | 25% |

| Density | 4.51 g/cm³ |

Product Attributes:

- High purity titanium ensures excellent weldability and corrosion resistance.

- Uniform diameter and smooth surface for consistent welding performance.

- Exceptional strength-to-weight ratio for lightweight yet durable welds.

- Low thermal conductivity minimizes distortion during welding.

Product Functions:

Grade 1 titanium welding wire (Gr1) serves specific functions primarily in welding applications due to its purity and weldability. Here are some of its key product functions:

Welding Applications: Titanium mig welding wire is primarily used for welding pure titanium and dissimilar metals where high corrosion resistance and biocompatibility are required. It is commonly used in industries such as aerospace, marine, medical, and chemical processing for joining titanium components or fabricating structures.

Aerospace Welding: It finds extensive use in the aerospace industry for welding aircraft components and structures. It is used in the manufacture of airplane outlines, fuselage boards, motor parts, and other basic parts where lightweight, high strength, and consumption opposition are fundamental.

Medical Device Fabrication: The biocompatibility and corrosion resistance of Gr1 titanium make it suitable for manufacturing medical implants and devices. It is used in the fabrication of surgical implants, orthopedic devices, dental prosthetics, and medical instruments where high purity and inertness are required to ensure compatibility with the human body.

Marine Welding: In the marine industry, it is employed for welding marine equipment and structures exposed to corrosive seawater environments. It is utilized in the construction of ship hulls, offshore platforms, underwater pipelines, and other marine infrastructure where resistance to corrosion and erosion is crucial for longevity and performance.

Chemical Processing Equipment: Titanium welding wire is used in the fabrication of chemical processing equipment such as reactors, heat exchangers, and piping systems. Its excellent corrosion resistance to aggressive chemicals and high temperatures ensures the integrity and reliability of critical process equipment in chemical plants, refineries, and pharmaceutical facilities.

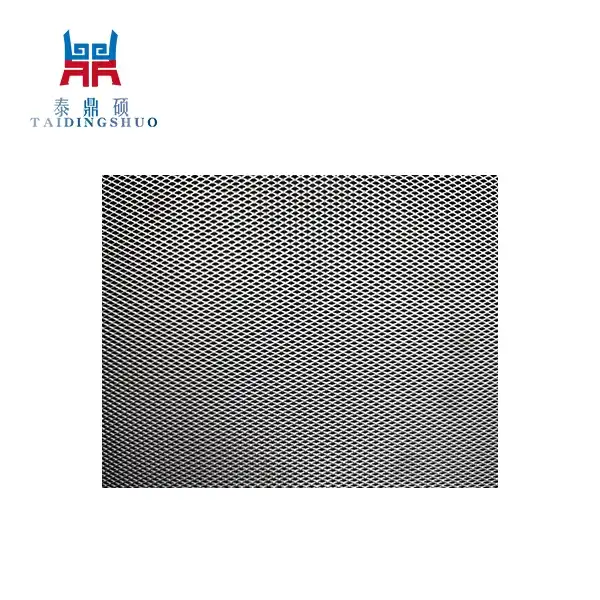

Custom Fabrication: It is utilized by metal fabricators and manufacturers for custom welding projects requiring the unique properties of titanium. It allows for the creation of bespoke components and structures tailored to specific industrial or commercial applications, ranging from architectural features to specialized machinery components.

Research and Development: Titanium welding wire suppliers may also be used in research and development laboratories for prototyping, experimentation, and testing of new welding techniques, materials, and applications. Its purity and consistency make it suitable for producing reliable test samples and prototypes for scientific studies and engineering projects.

Features:

- Pure titanium composition ensures superior weld strength and integrity.

- Consistent diameter and surface finish for smooth feeding and stable arc.

- Low interstitial impurities for clean, high-quality welds.

- Excellent resistance to corrosion and erosion in aggressive environments.

Advantages and Highlights:

- Compliant with stringent industry standards for quality and performance.

- Customizable dimensions to suit specific welding requirements.

- Exceptional mechanical properties for reliable weld joints.

- Wide range of applications across diverse industries.

Application Areas:

- Aerospace and aircraft manufacturing

- Marine and offshore engineering

- Chemical processing and petrochemicals

- Medical implants and prosthetics

- Automotive and transportation industries

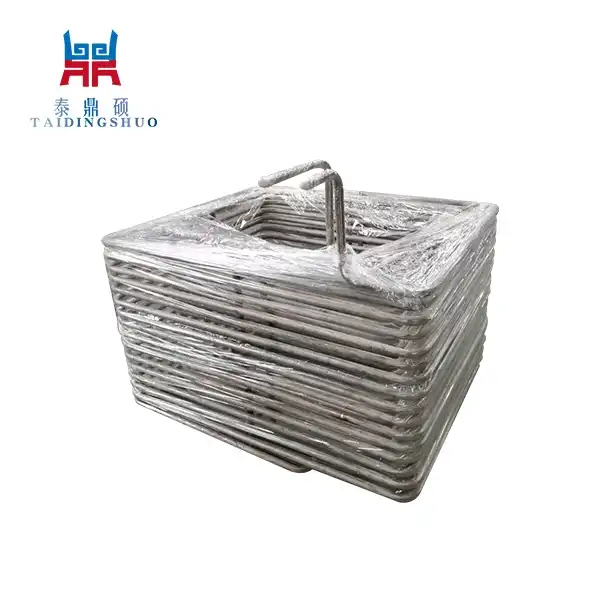

OEM Services:

Tai Ding Shuo Industrial Co., Ltd. offers comprehensive OEM services for titanium welding wire suppliers. We can customize the wire diameter, length, and packaging according to your specifications. Our experienced team ensures timely delivery of high-quality OEM products to meet your exact requirements.

Certifications:

FAQs:

-

What is the immaculateness of titanium welding wire?

-

Gr1 Titanium Welding Wire is produced using monetarily unadulterated titanium with a virtue of 99.5% or higher.

-

Can the welding wire's diameter and length be changed?

-

Yes, our dimensions can be changed to meet specific welding requirements. For more data on customization choices, kindly reach out to us.

-

Is it appropriate for welding in destructive environments?

-

Yes, it offers magnificent erosion opposition, making it reasonable for welding in forceful conditions like marine and synthetic handling businesses.

Material Properties and Details:

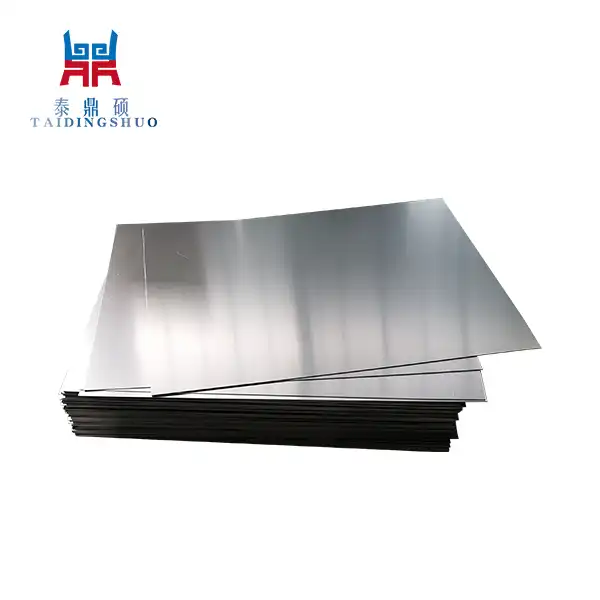

- Commercially pure titanium (Grade 1)

- High purity (>99.5%)

- Low interstitial impurities

- Excellent corrosion resistance

- Lightweight and high strength

About Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of titanium mig welding wire. We adhere to strict quality control measures and have obtained various standard and customized certifications, ensuring the highest quality of our products. Our comprehensive testing reports guarantee the performance and reliability of our welding wire. To meet the diverse requirements of our global clients, we provide OEM services, prompt delivery, and dependable packaging options. For inquiries or to place an order, please contact us at fujianguo@shelllaiqi.com.