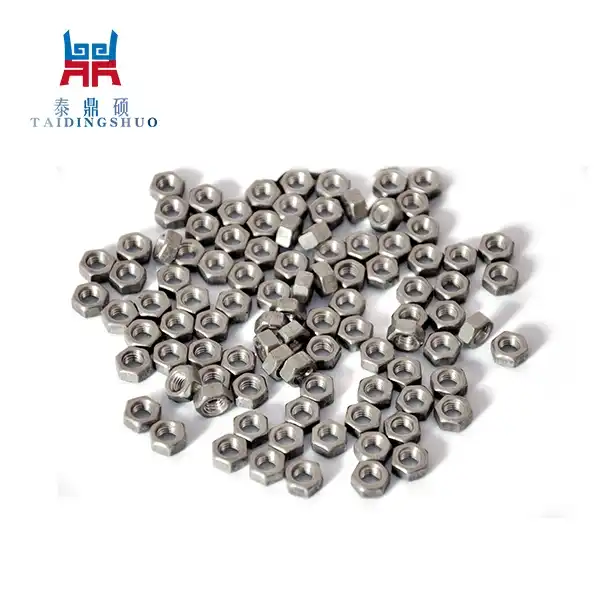

Product Description

Our Titanium non-standard screw is meticulously engineered to meet the highest standards of quality and performance. Crafted from premium-grade Titanium, these screws offer exceptional strength, durability, and corrosion resistance, making them ideal for a wide range of applications across various industries.

Product Standards:

Our Custom Titanium Screw adheres to stringent quality standards, including ISO 9001:2015 certification, ensuring consistent quality and reliability.

Basic Parameters:

| Parameter | Value |

|---|---|

| Material | Titanium Grade 5 (Ti-6Al-4V) |

| Thread Type | Non-standard |

| Head Type | Various (Phillips, Torx, Allen, etc.) |

| Size Range | Customizable |

| Coating | None |

| Surface Finish | Polished |

| Tensile Strength | 950 MPa |

| Corrosion Resistance | Excellent |

Product Attributes:

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- Precision-engineered for optimum performance

- Versatile design for various applications

- Customizable to meet specific requirements

Product Functions:

The products serve various functions across industries due to their unique properties and customizable designs. Here are some key product functions:

Customized Specifications: Non-standard titanium screws can be tailor-made to meet specific requirements regarding dimensions, thread patterns, head shapes, and drive types. This customization allows them to fit precisely into unique applications where standard screws may not suffice.

Corrosion Resistance: Titanium's inherent corrosion resistance makes non-standard screws suitable for use in environments prone to rust and oxidation, such as marine, chemical, and medical settings. They maintain their integrity even in harsh conditions, ensuring long-lasting performance.

Strength and Durability: The products offer high strength and durability despite their lightweight nature. This makes them ideal for applications where reliability and structural integrity are paramount, such as aerospace, automotive, and industrial machinery.

Biocompatibility: Titanium is biocompatible, meaning it is well-tolerated by the human body and compatible with biological tissues. Non-standard titanium screws are commonly used in medical implants and surgical procedures, including orthopedic and dental applications.

Temperature Resistance: Titanium can withstand extreme temperatures, making non-standard screws suitable for use in environments with temperature fluctuations or high heat conditions, such as aerospace components and industrial machinery.

Electrical Conductivity: Titanium exhibits excellent electrical conductivity, making non-standard screws suitable for electrical and electronic applications where conductivity is crucial.

Chemical Inertness: Titanium is chemically inert, resisting reactions with most chemicals and acids. This property ensures the stability and integrity of non-standard screws in chemical processing equipment, laboratories, and industrial settings.

Overall, titanium non-standard screw offers versatility, reliability, and performance across a wide range of applications, making them a preferred choice in various industries. Their customizable nature allows them to address specific needs and challenges, contributing to enhanced efficiency and functionality in diverse settings.

Features:

- High-grade Titanium construction

- Non-standard thread design for specialized applications

- Precision machining for tight tolerances

- Smooth surface finish for enhanced aesthetics

- Resistant to extreme temperatures and harsh environments

Advantages and Highlights:

- Lightweight yet incredibly strong

- Exceptional resistance to corrosion and chemical attacks

- Customizable options for unique applications

- Consistent quality and reliability

- Long-lasting performance, reducing maintenance costs

Application Areas:

- Aerospace and aviation

- Automotive manufacturing

- Medical and dental equipment

- Marine and offshore engineering

- Petrochemical and chemical processing

OEM Services:

We offer comprehensive OEM services, allowing you to customize the products to meet your exact specifications. Our experienced engineers work closely with clients to develop tailored solutions that precisely match their requirements.

Certifications:

FAQs:

-

What is the lead time for custom orders?

- Lead times for custom orders vary depending on the complexity and quantity of the order. Contact us for specific timelines.

-

Can you provide test reports and certifications?

- Yes, we provide complete test reports and certifications, including material certifications and dimensional inspection reports.

-

Do you offer bulk discounts?

- Yes, we offer competitive pricing for bulk orders. Contact our sales team for a customized quote.

Material Properties and Details:

Titanium Grade 5 (Ti-6Al-4V) is a popular choice for engineering applications due to its excellent combination of strength, corrosion resistance, and light weight. This alloy exhibits superb mechanical properties, including high tensile strength and toughness, making it suitable for demanding environments.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of Titanium non-standard screw. With a commitment to quality and innovation, we offer a comprehensive range of standard and customized screws to meet the diverse needs of our global clientele.

Our company is certified to ISO 9001:2015 standards, ensuring that our products consistently meet the highest quality standards. We provide complete test reports and certifications, along with OEM services to accommodate specific requirements.

For inquiries or orders, please contact us at fujianguo@shelllaiqi.com. Experience the reliability and performance of our Tailored Titanium Bolt for your next project.