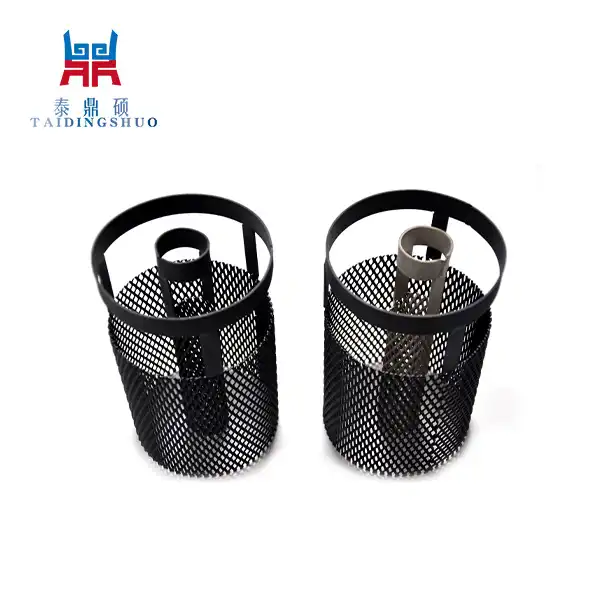

Product Description

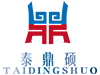

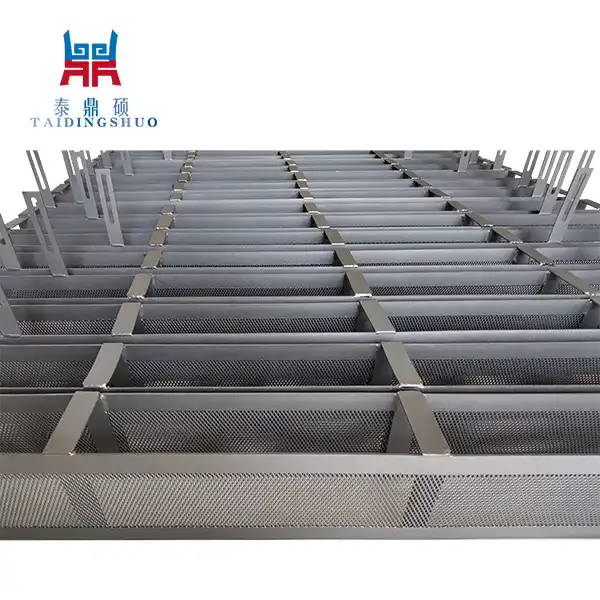

The essential capability of our Titanium anode is to work with the electroplating system by giving a steady and proficient electrical flow dispersion. It advances the testimony of iridium onto the substrate, guaranteeing uniform covering thickness and superb surface completion. The robust construction of the anode ensures consistent performance over long periods, reducing downtime and costs associated with maintenance.

Product Basics:

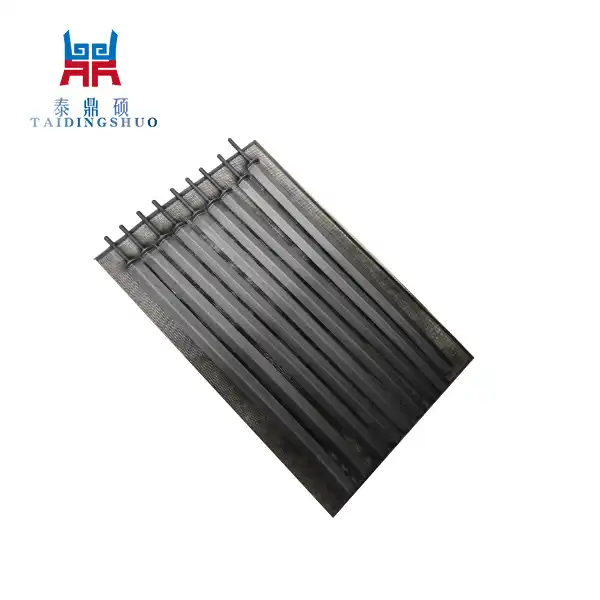

| Parameters | Details |

|---|---|

| Material | Titanium |

| Coating Material | Iridium |

| Shape | Customizable |

| Dimensions | Customizable |

| Current Density | Up to 5000 A/m² |

| Working Temperature | Up to 80°C |

| Connection Type | Threaded, Flanged, Welded, or Customized |

| Lifetime | Over 5 years |

Product Attributes:

For iridium plating, our Titanium anode has outstanding corrosion resistance, high conductivity, and durability. Made from high-grade titanium, the anode guarantees life span and unwavering quality in different plating applications. The iridium covering upgrades the surface properties, giving incredible bond and uniform plating results.

Features:

Presenting our Iridium Plating Titanium Anodes, a state of the art arrangement designed to upgrade the electroplating system for iridium-covered applications. This specialized anode set the standard for metal finishing with a plethora of features that improve its performance and dependability.

First and foremost, our Titanium Anode for Iridium Plating is made with great care from high-grade titanium. This makes it durable and resistant to corrosion even in the harshest electroplating conditions. It is a cost-effective investment for industrial applications due to its robust construction, which ensures long service life and consistent performance.

In addition, our anode is precisely crafted to facilitate the uniform and efficient iridium deposition onto substrates. Its upgraded surface region and cathode design empower exact command over current dispersion, limiting the gamble of lopsided covering thickness and guaranteeing impeccable outcomes without fail.

Additionally, our Titanium Anode for Iridium Plating is adaptable, making it suitable for a wide range of iridium-plating applications in a variety of sectors, such as aerospace, electronics, and jewelry production. Whether utilized for improving the sturdiness of aviation parts or conferring conductivity to electronic gadgets, this anode conveys uncommon outcomes with unparalleled unwavering quality.

In rundown, our Titanium Anode for Iridium Plating remains as a demonstration of development and greatness in electroplating innovation, furnishing makers with an unrivaled answer for accomplishing top notch iridium coatings productively and really.

Advantages and Highlights:

High conductivity for efficient plating;

customizable design to meet specific requirements;

exceptional resistance to corrosion;

dependable performance over long periods;

enhanced surface properties with iridium coating.

Application Areas:

Our Titanium anode for iridium plating is used across a range of ventures, incorporating:

Electronics: Upgrading conductivity and erosion opposition in electronic parts.

Aerospace: Working with the security and execution of basic aviation parts.

Automotive: enhancing automotive components' aesthetics and durability.

Jewelry: enhancing the longevity and visual appeal of intricate jewelry pieces.

Medical Equipment: ensuring that medical implants and instruments are biocompatible and resistant to corrosion.

Chemical Treatment: Supporting different synthetic cycles with consumption safe coatings and completions.

In every one of these areas, our Titanium anode for iridium plating fills in as a foundation for accomplishing exact and dependable electroplating results, fulfilling the rigid guidelines of current assembling necessities.

OEM Services:

We offer OEM administrations to meet the extraordinary prerequisites of our grade 1 titanium anode supplier. Custom Titanium anodes can be designed and manufactured by our knowledgeable staff in close collaboration with customers.

Certifications:

FAQs:

Q: How long does the titanium anode used in iridium plating last?

A: Under normal operating conditions, our anodes can last for more than five years.

Q: Is it possible to modify the anode's dimensions and shape?

A: Yes, we provide options for customization to meet our customers' specific needs.

Q: What is the anode's maximum supported current density?

A: Our anodes can uphold current densities of up to 5000 A/m².

Material Properties:

- Titanium: High strength-to-weight ratio, excellent corrosion resistance, biocompatibility.

- Iridium: Extremely corrosion-resistant, high melting point, excellent catalytic properties.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Modern Co., Ltd. is an expert maker and provider of Titanium anode for iridium plating. To guarantee the highest possible standards of product excellence, we adhere to stringent quality control procedures. Our anodes are made in consistence with industry standards and guidelines, and we give different norm and tweaked certificates and test reports for quality confirmation.

To meet the diverse requirements of our global clientele, we provide OEM services in addition to our extensive product line. Our devoted group is focused on giving quick conveyance, secure bundling, and solid client care. Please contact us at fujianguo@shelllaiqi.com for Titanium anode for iridium plating inquiries and orders.