Product Description

Tai Ding Shuo Industrial Co., Ltd.'s titanium anodes for rhodium plating are meticulously crafted to meet the highest quality and performance standards in the electroplating industry. Our anodes are designed utilizing premium-grade titanium material, guaranteeing toughness, effectiveness, and steady outcomes in the rhodium plating process.

Product Standards:

Our titanium anodes for rhodium plating meet international electroplating standards, ensuring their dependability and effectiveness across a wide range of plating processes. To deliver products that meet or exceed customer expectations, we strictly adhere to industry regulations and quality control measures.

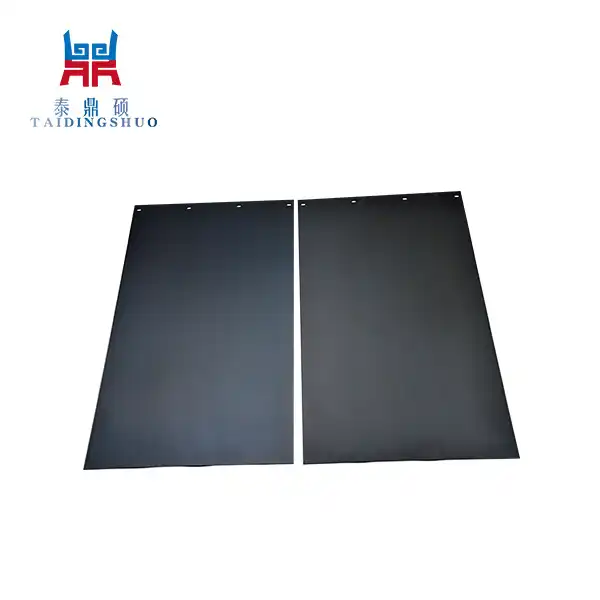

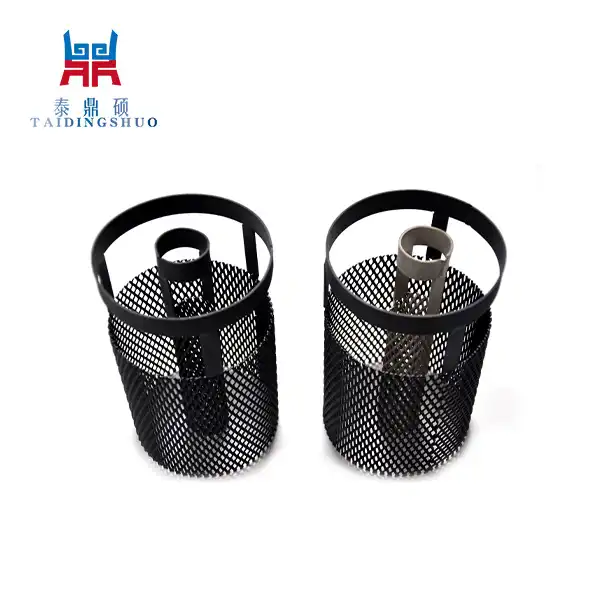

Basic Parameters:

| Parameter | Specification |

|---|---|

| Material | Titanium Grade 1 or Grade 2 |

| Coating Material | Mixed Metal Oxide (MMO) |

| Dimensions | Customized sizes available |

| Coating Thickness | 10-20 microns |

| Current Efficiency | ≥ 90% |

| Working Temperature | Up to 80°C |

| pH Range | 1-12 |

| Lifespan | Long-lasting |

Product Attributes:

Superior Resistance to Corrosion: endures harsh plating conditions.

Excellent conductivity of electricity: assures effective current transfer.

Distribution of the current uniformly: Advances steady plating results.

Long Help Life: Offers expanded solidness and dependability.

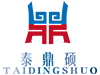

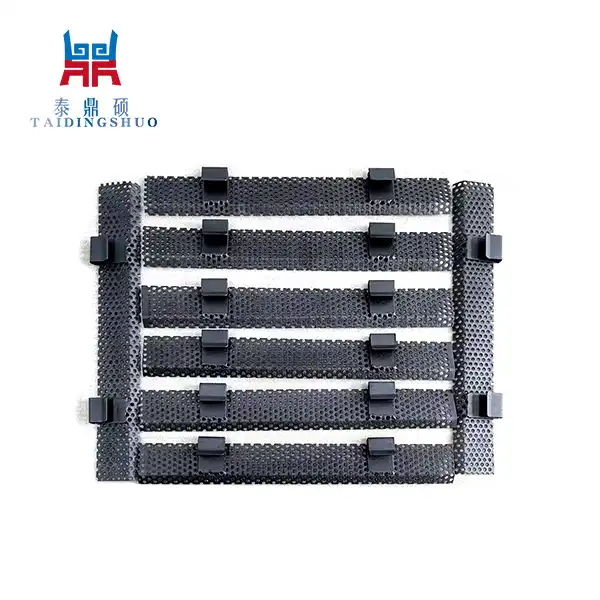

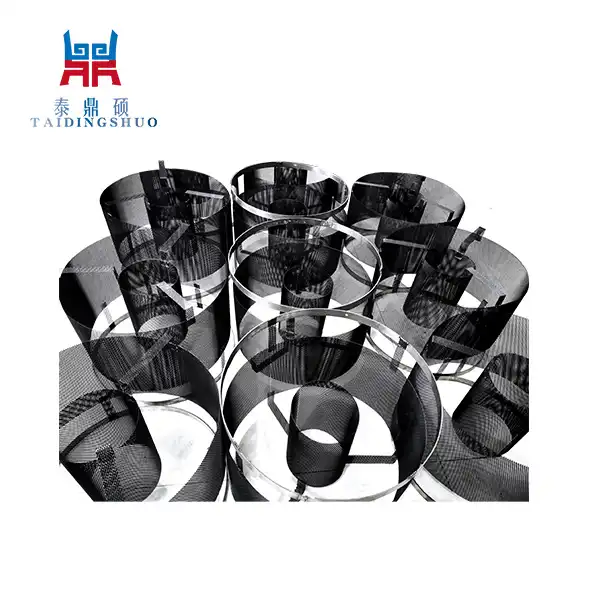

Designs that can be changed: tailored to specific requirements and plating setups.

Sustainable and eco-friendly: Produced using naturally capable materials.

Product Functions:

By ensuring uniform rhodium deposition on the surface of the substrate and providing a stable electrical current, titanium anodes make the rhodium plating process easier. The anodes really forestall erosion, subsequently broadening the life expectancy of the plating arrangement and keeping up with steady plating quality.

Features:

Titanium Construction that Lasts: designed to stand up to the rigors of rhodium plating processes.

Rhodium-Advanced Plan: designed specifically for optimum grade 1 titanium anode factories performance

Flexible Similarity: Viable with different plating arrangements and strategies.

Accuracy Designing: ensures high-quality plating results that are consistent.

Simple Establishment and Upkeep: simplifies operator setup and maintenance procedures.

Versatile Choices: obtainable in a variety of sizes and configurations to meet the requirements of various applications.

Advantages and Highlights:

Upgraded Strength: Titanium development guarantees enduring execution in requesting plating conditions.

Ideal Plating Results: enables uniform and high-quality rhodium plating for a superior finish on the surface.

Options for Customization: Tailorable plans oblige explicit plating necessities and arrangements.

Environmental stewardship: Eco-accommodating materials add to supportable plating rehearses.

Cost-Effectiveness: A cost-effective option for plating operations is provided by its long service life and dependable performance.

Application Options: suited to a wide range of sectors, including automotive, electronics, jewelry, and more.

Performance that is consistent: Accuracy designing guarantees predictable and dependable plating results a large number of bunches.

Application Areas:

Industry of Jewelry: ideal for putting precious metal plating on jewelry to make it look better and last longer.

The Production of Electronics: Appropriate for plating electronic parts to further develop conductivity and erosion opposition.

Car Area: Utilized in the plating of auto parts for beautiful purposes and consumption assurance.

Engineering in Aerospace: used in the aerospace industry to finish aircraft components' surfaces and prevent corrosion.

Clinical Gadget Creation: Used for plating clinical gadgets to guarantee biocompatibility and life span.

Conservation of Art: Utilized in the reclamation of compelling artwork and models to resuscitate their appearance and safeguard against debasement.

PCB (Printed Circuit Board) Manufacture: used to improve the conductivity and dependability of circuit boards.

OEM Services:

Customers can tailor Rhodium Plating Titanium Anodes to their specific requirements through Tai Ding Shuo Industrial Co., Ltd.'s comprehensive OEM services. Our accomplished group teams up intimately with clients to plan and make custom-made arrangements that meet their extraordinary electroplating needs.

Certifications:

FAQs:

Q: What are the advantages of involving Titanium anodes for rhodium plating?

A: Titanium anodes offer predominant erosion opposition, magnificent conductivity, and long help life, bringing about improved plating effectiveness and quality.

Q: Is it possible to modify the anode dimensions?

A: Yes, we offer custom sizing options to meet our customers' varied requirements.

Q: Do your products meet international requirements?

A: Indeed, our Titanium anodes for rhodium plating stick to severe quality norms and administrative prerequisites.

Q: Do you provide services to OEMs?

A: Totally, we work in OEM fabricating and can fit our items to your particulars.

Material Properties and Details:

Titanium, renowned for its exceptional corrosion resistance and biocompatibility, serves as the ideal substrate material for electroplating applications. The anodes are coated with Mixed Metal Oxide (MMO) to further enhance their conductivity and durability in harsh plating environments.

Tai Ding Shuo Industrial Co., Ltd.:

As a professional manufacturer and supplier of titanium anodes for rhodium plating, Tai Ding Shuo Industrial Co., Ltd. is committed to delivering excellence in quality and service. We provide various standard and customized certifications, complete test reports, and support OEM manufacturing. Our fast delivery, secure packaging, and dedicated customer support ensure a seamless experience for our global clientele. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.

With Tai Ding Shuo Industrial Co., Ltd., you can trust in superior products and reliable partnerships for all your electroplating needs.