Product Description

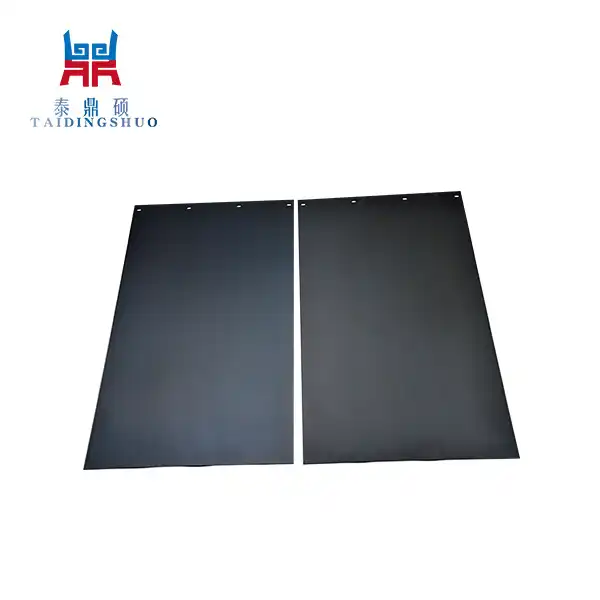

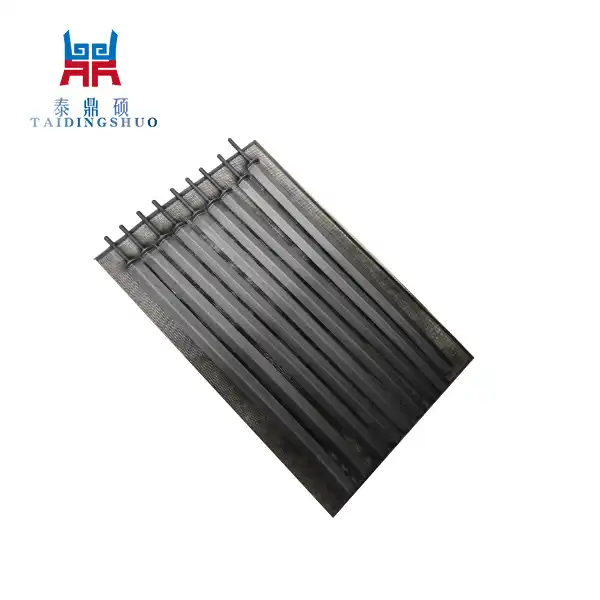

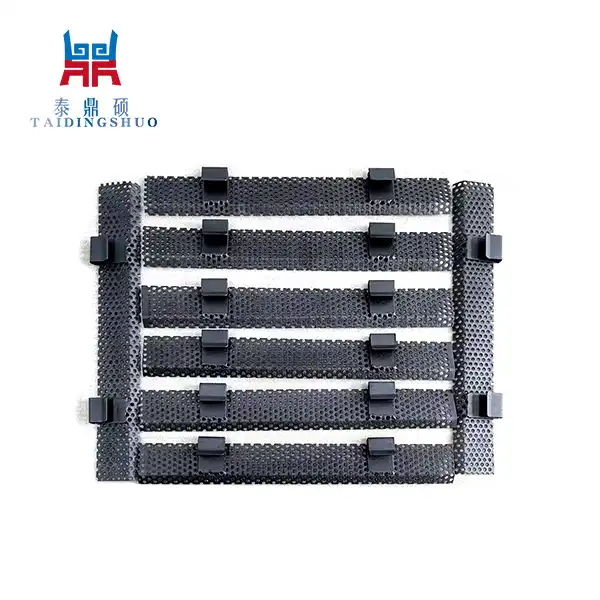

Our Titanium Anode for Copper Plating offers a scope of cutting edge capabilities custom fitted to hoist your copper plating cycles higher than ever of effectiveness and execution.

1. Enhanced Durability: Produced using incredible titanium, our anode is intended to persevere through the horrible conditions of copper plating conditions, ensuring long stretch strength and unflinching quality.

2. Exceptional Utilization Resistance: Our anode's disintegration safe properties ensure postponed utilitarian life, regardless, when presented to disastrous copper plating game plans, diminishing the prerequisite for standard replacements and backing.

3. Optimized Conductivity: With predominant conductivity, our titanium anode works with useful copper molecule move during plating, propelling uniform articulation and achieving unrivaled grade, smooth copper coatings on substrates.

4. Consistent Plating Results: The uniform current spread given by our anode ensures solid plating thickness and surface consummation across the entire substrate, restricting defects and redesigning thing quality.

5. Reduced Energy Consumption: By growing current viability and restricting voltage requirements, our product helps lower energy usage during the copper plating process, provoking expense speculation assets and normal benefits.

6. Versatile Compatibility: Reasonable with a broad assortment of copper plating courses of action and substrates, our anode offers adaptability and flexibility for various present day applications, including devices, vehicle, and breathing new live into coatings.

7. Environmental Sustainability: Our anode clears out the prerequisite for unsafe added substances by and large used in standard copper plating processes, propelling a cleaner, even more innocuous to the biological system plating action.

8. Ease of Integration: Expected for straightforward foundation and blend into existing copper plating courses of action, our product deals with the upgrade cycle and cutoff points extra electric anodizing titanium, taking into account predictable execution and quick improvements in plating execution.

Experience the state of the art innovation and unrivaled usefulness of our Titanium Anode for Copper Plating, and open the potential for prevalent copper plating brings about your industry.

Product Basics:

| Parameter | Description |

|---|---|

| Material | Titanium |

| Coating Material | Mixed Metal Oxides (MMO) |

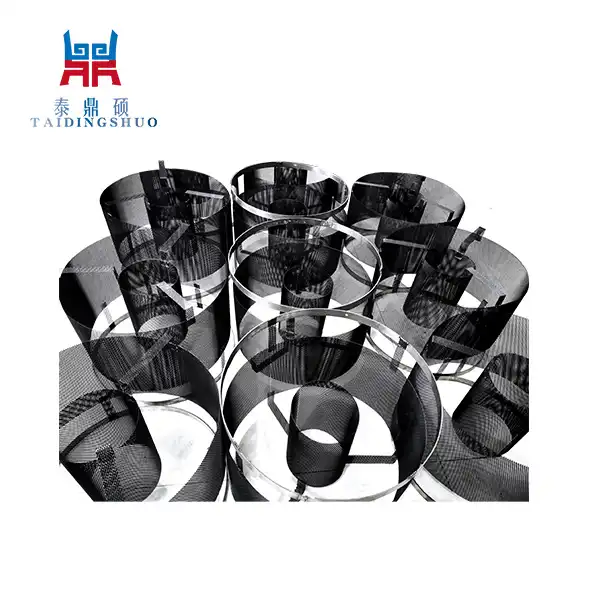

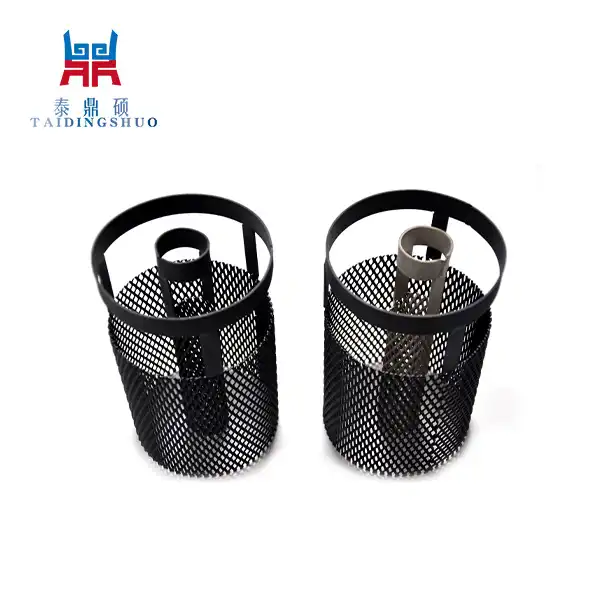

| Shape | Rectangular, cylindrical, or customized shapes |

| Coating Thickness | 5-15 microns |

| Current Density | Up to 2000 A/m² |

| Working Temperature | Up to 80°C |

| pH Range | 1-12 |

| Dimension | Customizable |

Product Standards:

- Manufactured in compliance with ASTM B265 standard.

- Coating complies with ASTM B 338 Grade 1 standards.

Product Attributes:

- Corrosion resistance.

- High current efficiency.

- Long service life.

- Excellent conductivity.

- Stable performance.

Features:

- Corrosion Resistance: Titanium material ensures durability and resistance to corrosion, extending the lifespan of the anode.

- High Current Efficiency: Optimized design and coating maximize current efficiency, leading to reduced electric anodizing titanium consumption.

- Customization: Available in various shapes and dimensions to suit specific plating requirements.

- Stable Performance: Consistent plating results over prolonged usage due to the stable and uniform coating.

- Wide pH Range Compatibility: Suitable for plating applications across a wide pH range, enhancing versatility.

- Easy Installation: Lightweight and easy to handle, facilitating installation in diverse plating setups.

Advantages and Highlights:

- Enhanced corrosion resistance compared to conventional anode materials.

- Superior current distribution for uniform plating.

- Customizable dimensions and shapes for versatile applications.

- Longevity and durability ensure cost-effectiveness over time.

Application Areas:

- Electronics industry for PCB manufacturing.

- Automotive industry for decorative and functional plating.

- Aerospace industry for corrosion protection.

- Jewelry and fashion accessories manufacturing.

- Plumbing and sanitary fittings production.

OEM Services:

We offer OEM services to meet specific client requirements, including customized shapes, sizes, and coatings.

Certifications:

FAQs:

-

What is the typical lifespan of Titanium anodes for copper plating?

- With proper maintenance, our anodes can last several years, depending on the application and operating conditions.

-

Can you provide technical support for installation and operation?

- Yes, our technical team can provide assistance with installation guidelines and operational recommendations.

-

Do you offer testing services for plating quality?

- Yes, we provide testing services to ensure the quality and performance of the plating process.

Material Properties:

- Titanium: Lightweight, strong, and highly resistant to corrosion, making it an ideal material for anode construction.

- Mixed Metal Oxides (MMO) Coating: Provides high conductivity and corrosion resistance, ensuring efficient and durable performance.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a reputable manufacturer and supplier of Titanium anodes for copper plating. We adhere to stringent quality standards and offer various standard and customized certifications to meet diverse client needs. Our products are accompanied by comprehensive test reports, ensuring reliability and performance. We support OEM requirements and guarantee fast delivery with secure packaging. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.

For professional buyers and global dealers seeking reliable Titanium anode for copper plating, Tai Ding Shuo Industrial Co., Ltd. is your trusted partner for high-quality solutions.