Product Description

In the domain of electrolytic assembling, the use of titanium anode has arisen as a urgent headway, especially in the creation cycles of copper foil. This presentation explains the transformative effect of it in upgrading the proficiency, maintainability, and cost-viability of copper foil creation.

Generally, the electrolytic creation of copper anodization of titanium foil has been laden with difficulties like erosion, energy utilization, and restricted life expectancy of ordinary anodes. Be that as it may, the reconciliation of it has reformed this scene by offering unmatched protection from consumption, accordingly expanding the functional life expectancy of electrolytic cells. This erosion opposition converts into massive expense reserve funds through diminished margin time and upkeep costs.

Also, it work with higher current densities, prompting improved efficiency in copper foil producing. The unrivaled conductivity of titanium guarantees effective electrochemical responses, bringing about enhanced statement rates and further developed item quality. Subsequently, makers can accomplish higher throughput without settling on the trustworthiness of the copper foil.

Moreover, the reception of titanium Anode for Electrolytic Manufacturing of Copper Foil lines up with the developing accentuation on supportability inside the assembling area. Contrasted with customary toxic anodes, titanium partners dispose of the gamble of weighty metal defilement in the electrolyte, relieving ecological worries and administrative consistence issues. This eco-accommodating property highlights the responsibility of the business towards capable creation rehearses.

Notwithstanding functional advantages, the adaptability of it empowers customization to suit explicit cycle prerequisites. Whether it be electrorefining, electrowinning, or electroplating applications, it offer versatility and unwavering quality across different electrolytic cycles.

The consolidation of it denotes a change in outlook in the electrolytic assembling of copper anodization of titanium foil, offering a strong blend of productivity, maintainability, and cost-viability. As the business keeps on embracing development, titanium Anode for Electrolytic Manufacturing of Copper Foil stand as a demonstration of the tireless quest for greatness in electrochemical innovation.

Product Standards:

- Compliant with industry standards for electrolytic manufacturing processes.

- Manufactured using advanced techniques to ensure consistent quality and performance.

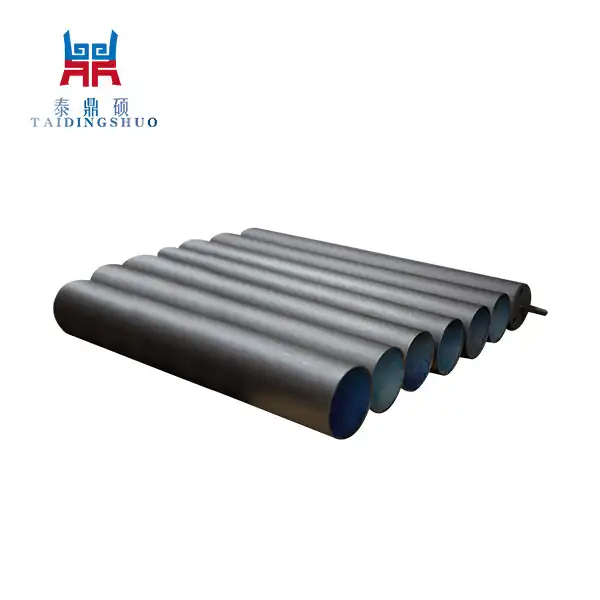

Basic Parameters:

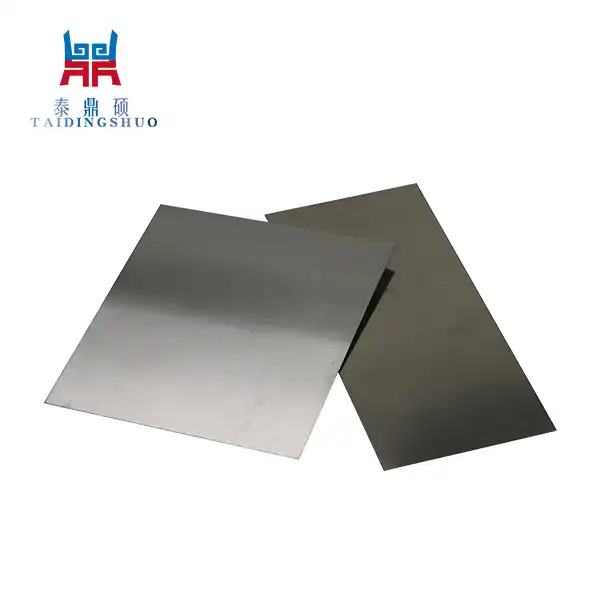

- Material: Titanium

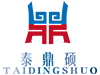

- Dimensions: Customizable to fit specific electrolytic cells

- Coating: Available with various coatings for enhanced performance and longevity

Product Attributes:

- High corrosion resistance, ensuring long-term durability in harsh electrolytic environments.

- Excellent conductivity for efficient titanium Anodes for Copper Foil Electrodeposition.

- Customizable designs to suit various electrolytic cell configurations.

Product Functions:

Our Titanium anode facilitates the electrolytic deposition of copper foil, providing a reliable and efficient method for manufacturing high-quality copper foils used in various industries.

Features:

- Robust construction for extended lifespan.

- Enhanced surface area for improved electrolytic efficiency.

- Flexible design options to accommodate different electrolytic setups.

Advantages and Highlights:

- Superior corrosion resistance compared to traditional anode materials.

- Consistent performance over extended periods, minimizing downtime.

- Customization options available to meet specific customer requirements.

Application Areas:

- Electronics industry: Used in the production of circuit boards and titanium Anodes for Copper Foil Electrodeposition.

- Energy storage: Employed in battery manufacturing processes.

- Aerospace and automotive: Utilized for lightweight and durable components.

OEM Services:

We offer OEM services to meet the unique specifications and requirements of our clients, ensuring optimal performance and compatibility with existing electrolytic systems.

Certifications:

FAQs:

- Can you provide custom sizes for our specific electrolytic cell?

- Yes, we offer customizable dimensions to fit any electrolytic cell configuration.

- What sort of covering choices do you offer?

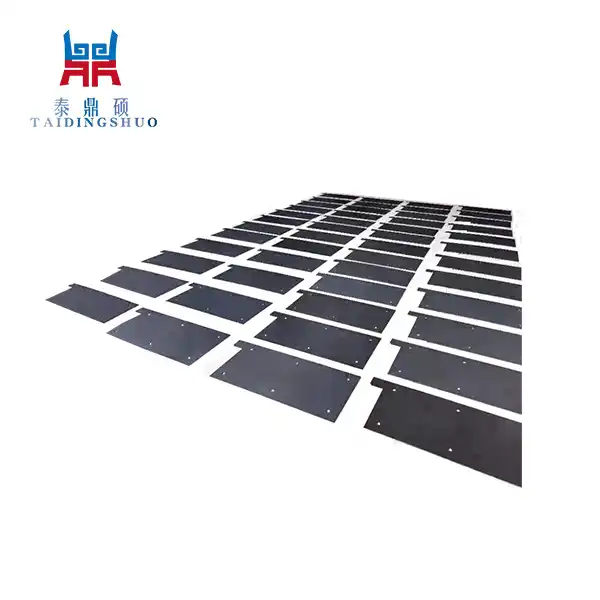

- We give a scope of coatings including platinum, ruthenium, and blended metal oxide coatings for improved performance.

- How long does your Titanium anode typically last?

- Our titanium Anode for Electrolytic Manufacturing of Copper Foil are designed for long-term durability and can withstand extended use in demanding electrolytic environments.

Material Properties and Details:

- Titanium: Known for its exceptional corrosion resistance and high strength-to-weight ratio, titanium is an ideal choice for electrolytic applications where durability and efficiency are paramount. Its inert nature ensures stable performance over time, making it a reliable option for electrolytic manufacturing processes.

About Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a reputable manufacturer and supplier of Titanium anodes for electrolytic manufacturing of copper foil. We specialize in providing high-quality products that meet international standards and customer specifications. Our commitment to excellence is reflected in our comprehensive quality certifications, complete test reports, and efficient OEM services. With fast delivery, meticulous packaging, and dedicated customer support, we strive to exceed expectations and build long-lasting partnerships with our clients worldwide. For inquiries or to request a quote, please contact us at fujianguo@shelllaiqi.com.