Product Description

The electrochemical formation of aluminum foil has witnessed a significant stride forward with the integration of titanium anode. This introduction delineates the transformative impact of it on bolstering the efficiency, sustainability, and cost-effectiveness of aluminum foil production.

Traditional methods of electrochemical aluminum anodized titanium foil formation grapple with challenges like corrosion, energy consumption, and the limited lifespan of conventional anodes. However, the incorporation of titanium electrodes has revolutionized this arena by offering unparalleled resistance to corrosion, thereby extending the operational lifespan of electrolytic cells. This corrosion resistance translates into substantial cost savings through reduced downtime and maintenance expenses.

Moreover, theproduct facilitate higher current densities, leading to enhanced productivity in aluminum Foil Formation Titanium Anode manufacturing. The superior conductivity of titanium ensures efficient electrochemical reactions, resulting in optimized deposition rates and improved product quality. Consequently, manufacturers can achieve higher throughput without compromising the integrity of the aluminum foil.

Furthermore, the adoption of it aligns with the burgeoning emphasis on sustainability within the manufacturing sector. Compared to traditional anode materials, titanium counterparts eliminate the risk of heavy metal contamination in the electrolyte, mitigating environmental concerns and regulatory compliance issues. This eco-friendly attribute underscores the industry's commitment to responsible production practices.

Additionally, the versatility of it allows for customization to suit specific process requirements. Whether it's for electrowinning, electrorefining, or electroplating applications, titanium Anode for Electrochemical Formation of Aluminum Foil offer adaptability and reliability across diverse electrolytic processes.

The integration of it signifies a paradigm shift in the electrochemical formation of aluminum foil, offering a potent amalgamation of efficiency, sustainability, and cost-effectiveness. As the industry continues to embrace innovation, it emerge as a cornerstone of excellence in electrochemical technology, driving forward the aluminum Foil Formation Titanium Anode manufacturing sector with unparalleled efficiency and sustainability.

Product Basics Parameter Criteria:

| Property | Description |

|---|---|

| Material | High-grade Titanium |

| Coating | Platinum |

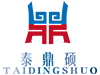

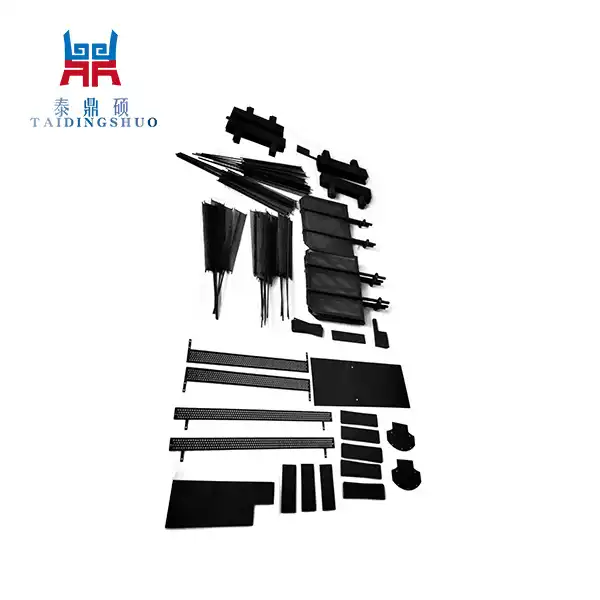

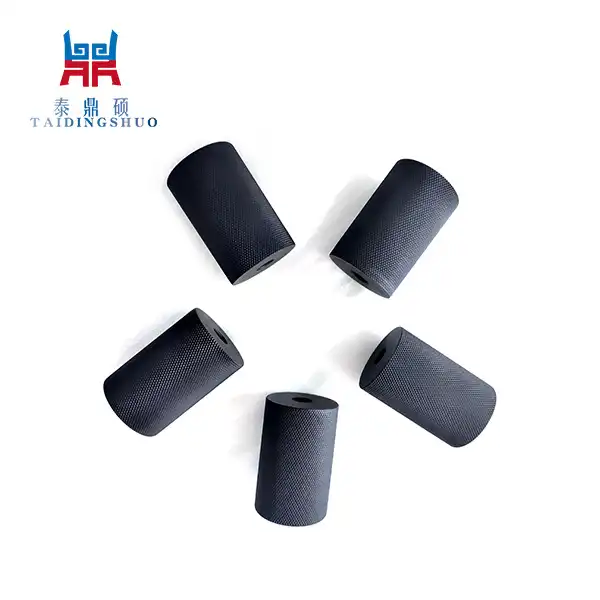

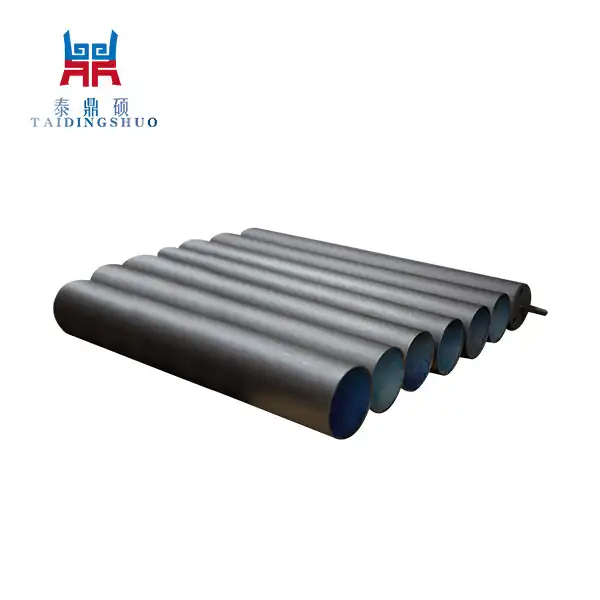

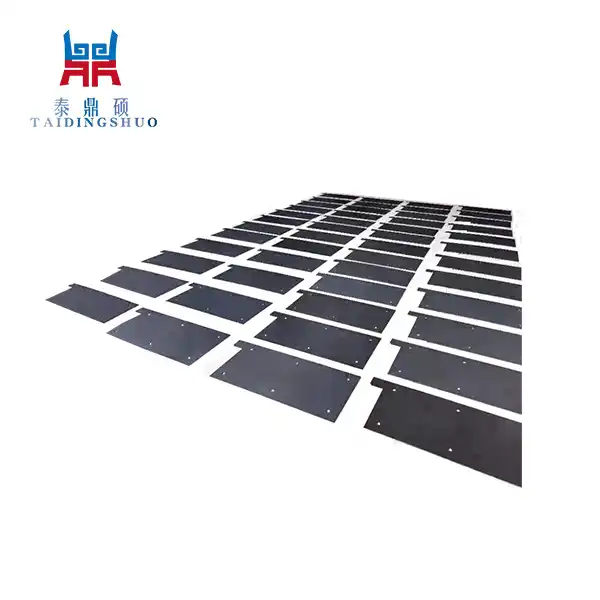

| Shape | Customizable (sheet, mesh, rod) |

| Current Density | Adjustable |

| Dimension | Customizable |

Material Properties and Details:

Titanium: Known for its extraordinary consumption obstruction and high solidarity to-weight proportion, titanium guarantees strength and life span in cruel electrochemical conditions

Platinum Coating: Provides enhanced catalytic activity, ensuring efficient electrochemical reactions and uniform aluminum deposition.

Product Standards:

- Compliant with international standards for electrochemical processes

- Manufactured using high-grade titanium materials

- Rigorously tested for durability, efficiency, and performance

Product Attributes:

- Corrosion resistance

- High conductivity

- Longevity

- Uniform electrochemical performance

Product Functions:

Our product facilitates the electrochemical formation of aluminum anodized titanium foil by providing a stable and efficient platform for the electrolytic process. It ensures uniform deposition of aluminum ions onto the cathode, resulting in the production of high-quality aluminum foil with precise thickness and excellent surface properties.

Features:

- Unrivaled consumption obstruction

- Incredible electrical conductivity

- Adaptable shapes and aspects

- Long help life

- Predictable performance

Advantages and Highlights:

- Upgraded efficiency

- Further developed item quality

- Diminished support costs

- Feasible and eco-accommodating assembling process

Application Areas:

- Aluminum foil creation industry

- Electrochemical assembling processes

- Metal completing applications

OEM Services:

We offer comprehensive OEM services to meet the specific requirements of our clients. From customized designs to tailored dimensions, we ensure that our titanium Anode for Electrochemical Formation of Aluminum Foil perfectly align with your electrochemical processes.

Certifications:

FAQs:

- What is the lifespan of your titanium anode?

- Our Titanium anode is designed for long-term use, with a lifespan varying based on operating conditions and maintenance.

- Can you customize the shape and dimensions of the anode?

- Yes, we provide customizable options to meet the unique requirements of our customers.

- Are your anodes compatible with different electrolytic cells?

- Absolutely, our anodes are designed to fit various types of electrolytic cells commonly used in aluminum foil production.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of titanium Anode for Electrochemical Formation of Aluminum Foil for electrochemical formation of aluminum foil. We offer a wide range of standard and customized solutions to meet the diverse needs of our global clientele. Our products are backed by comprehensive room certifications and complete test reports, ensuring compliance with international quality standards. We provide OEM services, fast delivery, and robust packaging solutions to ensure customer satisfaction. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.

With our expertise and commitment to excellence, we strive to be your trusted partner in electrochemical manufacturing processes, delivering superior products and unparalleled service to meet your evolving needs.