Product Description

The production of Titanium Anodes for Negative Electrode Foils has undergone a transformative evolution with the utilization of titanium anode. This introduction elucidates the pivotal role of it manufacturing in enhancing the efficiency, sustainability, and cost-effectiveness of negative electrode foil production.

Traditional methods of negative electrode foil production often encounter challenges such as corrosion, energy consumption, and the limited lifespan of conventional anodes. However, the incorporation of titanium electrodes has revolutionized this domain by offering unmatched resistance to corrosion, thereby prolonging the operational lifespan of electrolytic cells. This corrosion resistance translates into significant cost savings through reduced downtime and maintenance expenses.

Furthermore, the product enable higher current densities, leading to enhanced productivity in negative electrode titanium foil anode manufacturing. The exceptional conductivity of titanium ensures efficient electrochemical reactions, resulting in optimized deposition rates and improved product quality. Consequently, manufacturers can achieve higher throughput without compromising the integrity of the negative electrode foil.

Moreover, the adoption of it aligns with the escalating emphasis on sustainability within the manufacturing sector. In contrast to traditional anode materials, titanium counterparts eliminate the risk of heavy metal contamination in the electrolyte, addressing environmental concerns and regulatory compliance issues. This eco-friendly attribute underscores the industry's commitment to responsible production practices.

Additionally, the versatility of it allows for tailored production to meet specific process requirements. Whether it's for electroplating, electrowinning, or electrorefining applications, the product offer adaptability and reliability across diverse electrolytic processes.

The production of it represents a paradigm shift in negative electrode titanium foil anode manufacturing, offering a potent blend of efficiency, sustainability, and cost-effectiveness. As the industry continues to embrace innovation, it emerge as a cornerstone of excellence in electrochemical technology, driving forward the negative electrode foil production sector with unparalleled efficiency and sustainability.

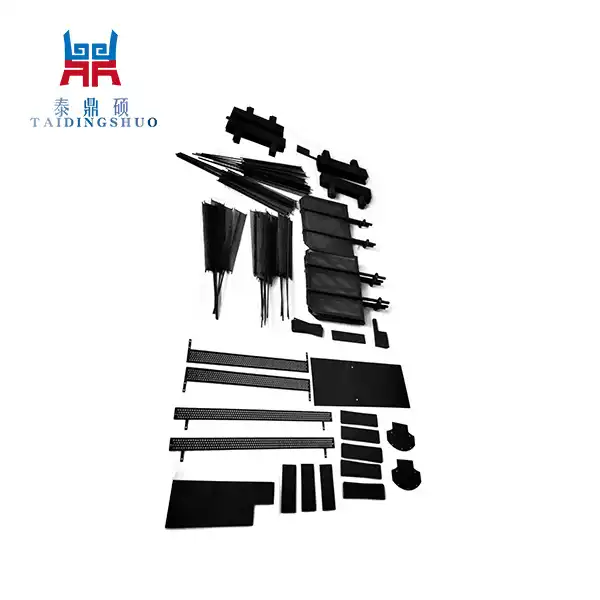

Basic Product Details:

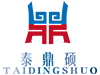

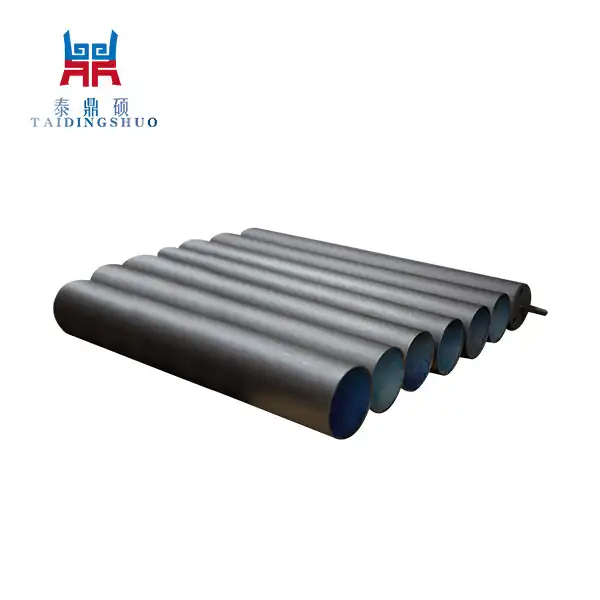

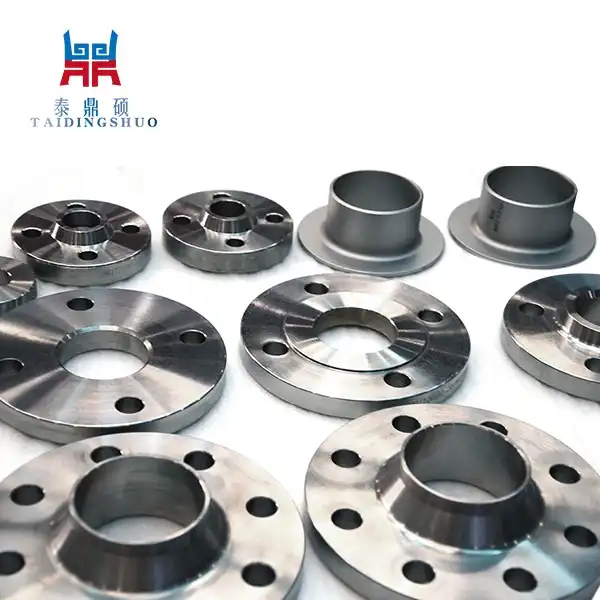

Our product for negative electrode Titanium Anode Fabrication for Electrode Foils are meticulously crafted using advanced manufacturing techniques to ensure superior quality and performance. These anodes are designed to meet the stringent requirements of diverse industries, offering exceptional reliability and durability.

Product Standards:

Our production of Titanium Anodes for Negative Electrode Foils adheres to industry-leading standards, ensuring compliance with quality benchmarks and specifications. We guarantee consistent quality and performance across all our products, meeting the expectations of even the most discerning customers.

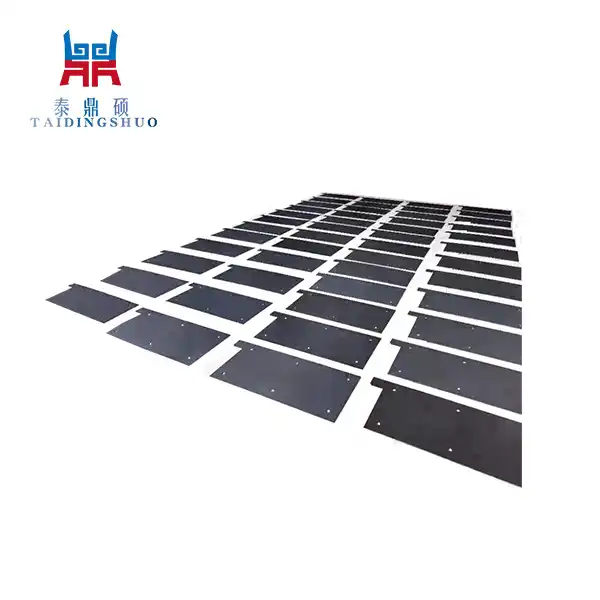

Basic Parameters:

| Parameter | Value |

|---|---|

| Material | Titanium |

| Coating Material | Mixed Metal Oxides |

| Thickness | 0.1mm - 1.0mm |

| Width | Up to 1000mm |

| Length | Customizable |

| Working Temperature | Up to 80°C |

Product Attributes:

- Corrosion resistance

- High conductivity

- Long lifespan

- Superior adhesion

- Excellent mechanical properties

Product Functions:

Our product for negative electrode Titanium Anode Fabrication for Electrode Foils are primarily used for electrochemical processes such as electrolysis, electroplating, and water treatment. They facilitate efficient and precise control over electrochemical reactions, ensuring optimal performance and productivity.

Features:

- Hearty development

- Uniform covering circulation

- Low upkeep

- Harmless to the ecosystem

- Wide similarity with different electrolytes

Advantages and Highlights:

- Enhanced durability for prolonged service life

- Consistent performance under harsh operating conditions

- Cost-effective solution compared to traditional materials

- Customizable dimensions to suit specific requirements

- Comprehensive technical support and assistance

Application Areas:

- Electroplating industry

- Chlor-alkali industry

- Water treatment plants

- Chemical manufacturing

- Metal finishing processes

OEM Services:

We offer OEM administrations to meet the novel determinations and prerequisites of our clients. Our accomplished group teams up intimately with clients to foster tailor-made arrangements that address their particular requirements, guaranteeing greatest fulfillment and worth.

Certifications:

FAQs:

-

What is the life expectancy of your titanium anode?

- Our titanium anode gloat a long life expectancy, commonly going from 5 to 10 years relying upon the working circumstances and support rehearses.

-

Could you at any point modify the elements of the anodes?

- Indeed, we offer adaptable aspects to oblige the particular necessities of our clients. Essentially furnish us with your determinations, and we will tailor the item appropriately.

-

Do you offer specialized help for establishment and support?

- Totally. Our group of specialists is accessible to offer complete specialized help and help all through the establishment, activity, and upkeep processes.

Material Properties and Details:

- Titanium: Known for its remarkable erosion obstruction and mechanical strength, titanium fills in as the essential material for our anodes, guaranteeing life span and unwavering quality.

Blended Metal Oxides (MMO): The covering material applied to the titanium substrate upgrades conductivity and gives predominant erosion opposition, guaranteeing ideal performance in different electrochemical applications.

About Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of production of titanium anodes for negative electrode foils. We are committed to delivering top-notch products that meet the highest industry standards. Our comprehensive range of certifications, complete test reports, and OEM support underscores our dedication to quality and customer satisfaction. For inquiries or to place an order, please contact us at fujianguo@shelllaiqi.com. Experience the difference with Tai Ding Shuo Industrial Co., Ltd.