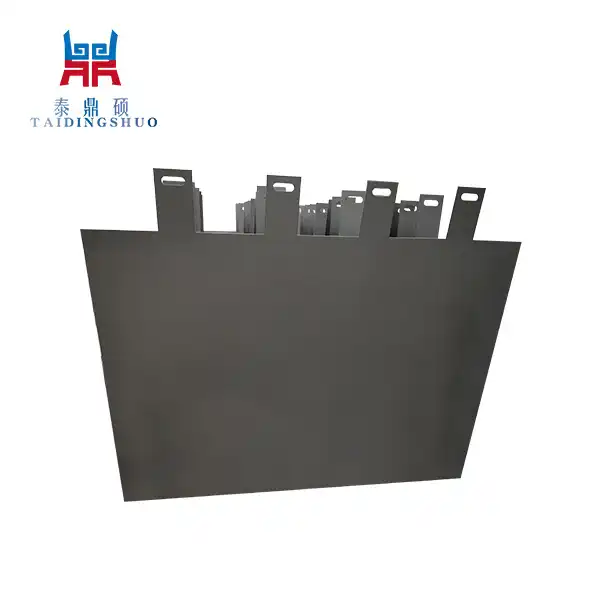

Product Description

Titanium anodes are fundamental parts in the electrocatalytic cycle of zinc sulfide, offering one of a kind properties that upgrade the productivity and viability of the response.It act as the catalyst for the electrochemical transformation of zinc sulfide into its components, zinc and sulfur, in this procedure. The production of zinc metal, batteries, and chemical synthesis are just a few of the many industrial applications for which this electrocatalytic reaction is essential.

The excellent resistance to corrosion of it in the electrocatalytic conversion of zinc sulfide is one of the primary benefits. High temperatures and harsh chemical environments are common in zinc sulfide electrocatalysis, which can degrade conventional anodes. The products notwithstanding, can endure these circumstances, guaranteeing a more extended life expectancy and reliable execution all through the electrocatalytic cycle.

Moreover, titanium anodes offer high synergist movement, working with the proficient transformation of zinc sulfide into zinc and sulfur. The electrocatalytic reaction kinetics of they are enhanced by their unique surface properties, resulting in increased conversion efficiency and faster reaction rates. This high synergist movement brings about a more practical and useful interaction for the creation of zinc from zinc sulfide.

Also, they are savvy and harmless to the ecosystem contrasted with elective impetus materials. They are a viable option for businesses looking to optimize their electrocatalytic processes while simultaneously lowering overall costs due to their lower initial cost and extended operational lifespan. By reducing energy use and waste production, the use of it also contributes to a more environmentally friendly process.

Additionally, they are adaptable and can be custom-made to explicit electrocatalytic necessities for zinc sulfide transformation. Their movable surface properties and arrangement consider customization in light of the ideal response conditions, empowering exact command over the electrocatalytic cycle boundaries. This adaptability guarantees ideal execution and effectiveness in the development of zinc from zinc sulfide.

In conclusion, titanium anodesanodically oxidized titanium are essential to the electrocatalytic conversion of zinc sulfide because they are cost-effective, resistant to corrosion, have high catalytic activity, and can be used in a variety of industrial applications. They are a crucial component for businesses looking to boost the effectiveness and long-term viability of their electrocatalytic processes for the production of zinc because of their distinctive properties. It is anticipated that it will continue to play a significant role as a catalyst in the electrocatalytic conversion of zinc sulfide as research and technology advance.

Product Standards:

- Compliant with international standards for electrochemical applications.

- Manufactured using advanced techniques to ensure consistency and quality.

Product Basics Knowledge Parameter Criteria:

| Parameter | Value |

|---|---|

| Material | Titanium |

| Coating | Mixed Metal Oxide (MMO) |

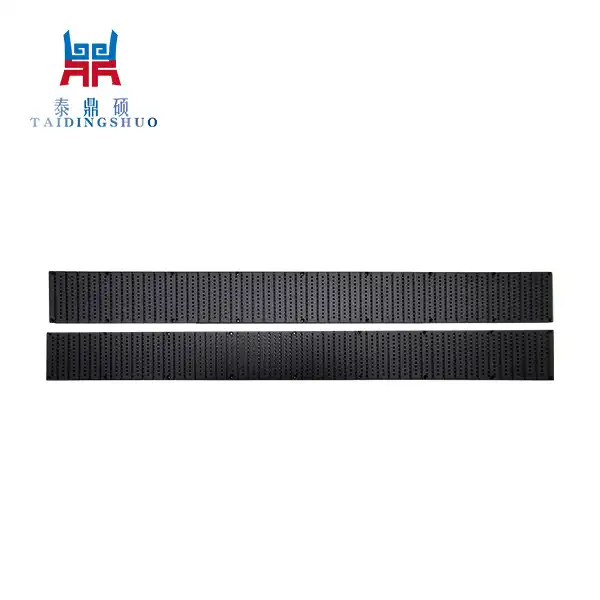

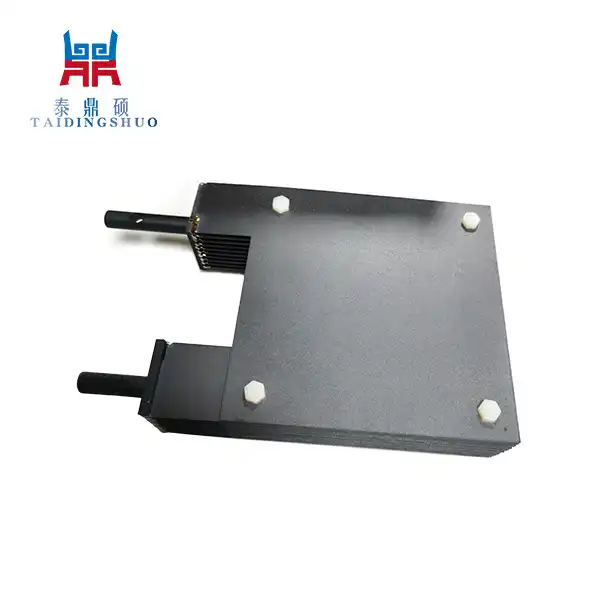

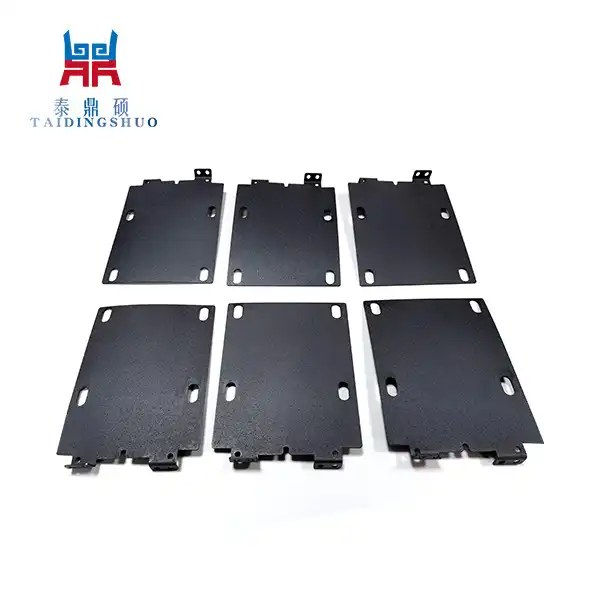

| Shape | Customizable |

| Dimensions | Tailored to customer needs |

| Current Density | High performance |

Basic Parameters:

- Material: Titanium

- Coating: Mixed Metal Oxide (MMO)

- Shape: Customizable (rod, plate, mesh, etc.)

- Dimensions: Tailored to customer requirements

- Current Density: High performance under varying current densities

Product Attributes:

- Corrosion Resistance: Exceptional resistance to corrosion, ensuring longevity.

- High Efficiency: Optimized design for enhanced electrocatalytic activity.

- Customizability: Tailored solutions available to meet specific application needs.

- Stability: Provides stable performance over extended periods.

- Environmental Compatibility: Eco-friendly and sustainable material choice.

Product Functions:

In the electrocatalytic change of zinc sulfide, Titanium Zinc Sulfide Electrocatalytic Anodes assume an essential part in working with the response and playing out various significant capabilities. Coming up next are the central components of it in the electrocatalytic pattern of zinc sulfide:

- Guarding Against Corrosion: Due to their exceptional resistance to corrosion, they are well-suited for use in the aggressive chemical environments that are typically encountered during the electrocatalytic conversion of zinc sulfide. The anodes' resistance to corrosion ensures their long-term durability and ensure consistent performance over extended operating times.

- Movement Synergist: It have a lot of catalytic activity, making electrochemical conversion of zinc sulfide into zinc and sulfur easier. The synergist properties of titanium further develop the reaction energy, provoking faster reaction rates and extended adequacy in the change cycle. This catalytic activity is necessary to achieve high conversion yields and maximize zinc production from zinc sulfide.

- Stability and dependability: It ensures stability and dependability in the electrocatalytic process by delivering consistent performance under a variety of reaction conditions. Their enthusiastic nature thinks about unending action without debasement or loss of synergist development, ensuring trustworthy and obvious results in the change of zinc sulfide.

- Cost-Effectiveness: They are a smart choice for electrocatalytic applications diverged from other stimulus materials. Because of their low initial costs and low maintenance requirements, the production of zinc from zinc sulfide saves money overall. The strength and life expectancy of it further overhaul their cost sufficiency by diminishing the necessity for unremitting replacements.

- Flexibility and personalization: To meet specific electrocatalytic requirements for the conversion of zinc sulfide, it can be altered. In light of their flexibility, specially crafts and surface changes can be made to further develop synergist execution in view of the response boundaries that are wanted. The electrocatalytic cycle can be definitively controlled with this customization ability, bringing about expanded efficiency and effectiveness.

- Benefits for the environment: By reducing energy consumption and reducing waste age, the use of it in the electrocatalytic transformation of zinc sulfide offers natural advantages. With regards to the fundamentals of green science and asset preservation, their sturdiness and proficiency help to make the most common way of delivering zinc all the more harmless to the ecosystem and maintainable.

In conclusion, the electrocatalytic conversion of zinc sulfide relies heavily on it because of their corrosion resistance, catalytic activity, stability, affordability, adaptability, and environmental friendliness. Their original properties make them a principal part in present day applications attempting to work on the viability and reasonability of zinc creation processes. As development moves, Titanium Zinc Sulfide Electrocatalytic Anodes should continue expecting a key part in redesigning the electrocatalytic change of zinc sulfide.

Features:

- Advanced Coating: Utilizes state-of-the-art Mixed Metal Oxide (MMO) coating for superior performance.

- Versatile Design: Customizable shape and dimensions to suit diverse applications.

- Longevity: Resilient construction ensures prolonged service life.

- High Performance: Optimized for efficient electrocatalytic activity.

Advantages and Highlights:

- Superior Corrosion Resistance: Withstands harsh chemical environments.

- Enhanced Efficiency: Maximizes electrochemical conversion efficiency.

- Tailored Solutions: Customizable to meet specific application requirements.

- Reliable Performance: Ensures consistent operation over extended periods.

- Cost-Effective: Long-term durability minimizes maintenance and replacement costs.

Application Areas:

- Wastewater Treatment Plants

- Electroplating Industries

- Metal Recovery Processes

- Chemical Manufacturing

- Mining Operations

OEM Services:

We provide comprehensive OEM services and custom solutions to meet our customers' specific needs. Our accomplished group works intimately with clients to foster redid items that line up with their particular applications and execution rules.

Certifications:

FAQs:

-

What is the typical future of the product for Electrocatalytic Zinc Sulfide?

Depending on the operating conditions, the lifespan can be anywhere from a few years to more than a decade.

-

Is it conceivable to adjust the anode to squeeze into existing frameworks?

Yes, we offer customization options to ensure compatibility with a wide variety of setups and configurations.

-

Is there technical support available for installation and maintenance?

Indeed, our specialized group offers thorough help the whole way through the item lifecycle, including guidance for establishment and upkeep.

Material Properties and Details:

The Titanium Anode for Electrocatalytic Zinc Sulfide is constructed from high-grade titanium, renowned for its exceptional corrosion resistance and mechanical strength. The anode is coated with a specialized Mixed Metal Oxide (MMO) layer, which significantly enhances its electrocatalytic properties, ensuring efficient and reliable performance in demanding environments.

About Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Modern Co., Ltd., a major manufacturer and supplier of electrochemical products, offers it for a wide range of uses. With long stretches of involvement and ability, we spend significant time in giving arrangements of excellent that meet the severe prerequisites of our worldwide clients.

As evidence of our obligation to quality and adherence to industry standards, we offer various authentications and test reports. Through our OEM services, customers can tailor products to meet specific requirements, ensuring optimal performance and compatibility with existing systems.

Please contact us at fujianguo@shelllaiqi.com if you have any inquiries or wish to learn more about our product for Electrocatalytic Zinc Sulfide. To effectively meet your requirements, we provide prompt delivery, secure packaging, and dedicated support.