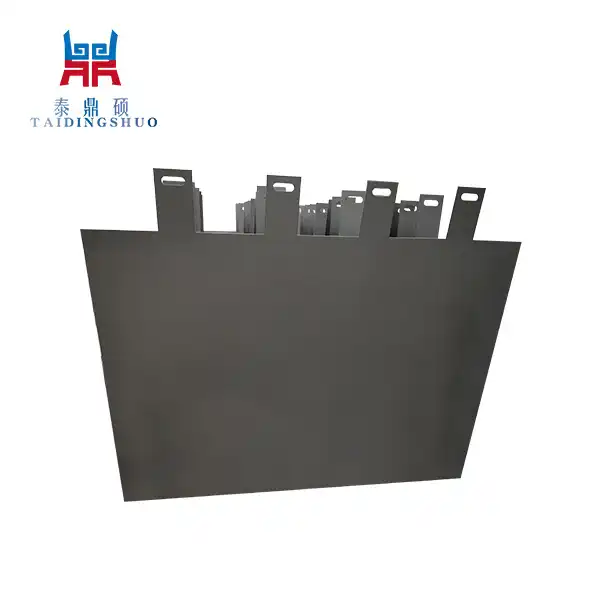

Product Description

Due to their exceptional properties and advantages in terms of execution, titanium anodes have emerged as a popular choice for the production of manganese dioxide. Manganese dioxide is a fundamental material used in various endeavors, including battery delivering, water treatment, and devices. Incorporating it into the manufacturing process has numerous benefits that improve product quality, efficiency, and cost-effectiveness.

One of the primary advantages is the superior resistance to corrosion of it used in the production of manganese dioxide. Because it is resistant to corrosion even in harsh chemical environments, titanium is an excellent material for electrolytic processes that produce manganese dioxide. This utilization obstacle ensures the life expectancy and strength of the anodes, provoking a more strong and consistent creation process.

During the production of manganese dioxide, efficient electrochemical reactions also require it with a high conductivity. The high conductivity of titanium considers fast electron move, achieving speedier reaction rates and better returns of manganese dioxide. This not just makes the creation cycle more useful generally, yet it additionally helps cut down on energy use and capitalize on assets.

Also, titanium anodes are more affordable than different materials that are often used in electrolytic cycles. Even though materials based on platinum may offer comparable performance, their significantly higher cost drives up production costs. Titanium, then again, is less expensive and simpler to find, settling on it a decent decision for organizations hoping to further develop how they make manganese dioxide.

There are a number of benefits to producing manganese dioxide using it, including superior corrosion resistance, high conductivity, and cost-effectiveness. As a result of these advantages, manufacturers in the manganese dioxide industry gain cost savings, enhanced product quality, and increased efficiency. Manganese Dioxide Industry Titanium Anodes are likely to play a significant role in improving production cycles and meeting industry requirements as the demand for high-quality manganese dioxide continues to grow.

Product Standards:

Our custom anodizing titanium for Manganese Dioxide Production adheres to the highest industry standards, including ASTM B265 for titanium materials and ASTM B348 for titanium alloy bars.

Basic Parameters:

| Parameter | Specification |

|---|---|

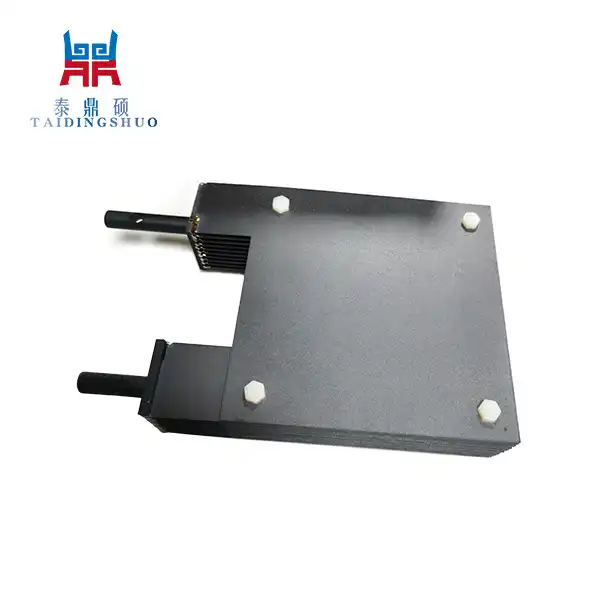

| Material | Titanium Grade 1 |

| Coating | Ruthenium-Iridium (Ru-Ir) |

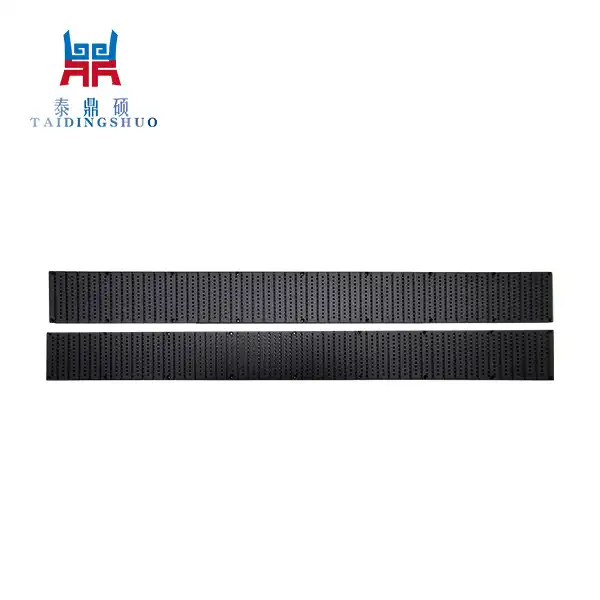

| Dimensions | Customizable |

| Current Density | Up to 2000 A/m² |

| Temperature Range | Up to 80°C |

| pH Range | 1-14 |

| Lifetime | 5-10 years |

Product Attributes:

- Corrosion resistance

- High conductivity

- Enhanced durability

- Customizable dimensions

- Excellent performance under high current densities

- Compatible with a wide pH range

- Minimal maintenance required

Product Functions:

Titanium anodes play a crucial role in the electrolytic cycles that lead to the formation of manganese dioxide and provide a few essential capabilities that are necessary for efficient and powerful assembly.

One of the primary purposes for which it are utilized in the production of manganese dioxide is their high resistance to corrosion. The anode can corrode if it is not adequately protected from electrolytic reactions and harsh chemical environments during manganese dioxide production. Titanium's extraordinary disintegration check ensures the life expectancy and durability of the anode, staying aware of the genuineness of the creation cycle and thwarting contamination of the manganese dioxide thing.

Furthermore,it give a latent and stable surface for the electrochemical responses that occur during the creation of manganese dioxide. The anode is where oxidation responses occur, making it simpler for manganese dioxide to be kept on its surface. This deposition process is necessary in order to obtain manganese dioxide of high quality and the desired properties for various industrial applications.

In addition, the high conductivity of it enables productive electron movement throughout the electrolytic cycle. Manganese dioxide's improved returns and faster response rates are made possible by its high conductivity, increasing the production cycle's overall efficiency. It works with effective electron move, which lessens energy use and expands asset usage, bringing about cost reserve funds for makers.

As a rule, Manganese Dioxide Industry Titanium Anodes assume a part in the creation of manganese dioxide by going about as a site for electrochemical responses, opposing erosion, and working with powerful electron move. Because they guarantee the quality, efficiency, and cost-effectiveness of the production process, they are a necessary component in the production of manganese dioxide. They are likely to continue to be a crucial innovation in streamlining production cycles and meeting industry requirements as the demand for high-quality manganese dioxide continues to grow.

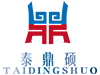

Features:

- Precise engineering for optimal performance

- Uniform coating for enhanced durability

- Versatile design adaptable to various electrolytic cells

- High current density capability for improved productivity

- Resistance to harsh chemical environments

Advantages and Highlights:

- Superior corrosion resistance compared to conventional anode materials

- Extended lifespan leading to reduced downtime and maintenance costs

- Enhanced efficiency in manganese dioxide production processes

- Customizable dimensions to fit specific application requirements

- Reliable performance under varying operating conditions

Application Areas:

Our product for Manganese Dioxide Production finds extensive usage in:

- Electrolytic manganese dioxide (EMD) production

- Batteries manufacturing

- Chemical synthesis processes

- Water treatment applications

OEM Services:

We provide complete OEM services, making it possible for customers to tailor anodes to their particular requirements, such as dimensions, coating materials, and current density requirements.

Certifications:

FAQs:

-

What is the lifespan of your product?

-

Our anodes typically last between 5 to 10 years, depending on operating conditions and maintenance practices.

-

Can you provide custom dimensions for the anodes?

-

Yes, we offer customization options to tailor the dimensions of the anodes to fit your specific application requirements.

-

Are your anodes compatible with high current densities?

-

Yes, our anodes are designed to withstand high current densities, ensuring optimal performance and productivity.

Material Properties and Details:

- Grade 1 Titanium: chosen for its superior resistance to corrosion and biocompatibility.

- Ruthenium-Iridium Covering: in corrosive environments, improves conductivity and durability.

About Tai Ding Shuo Industrial Co., Ltd:

Tai Ding Shuo Industrial Co., Ltd is a leading manufacturer and supplier of custom anodizing titanium for Manganese Dioxide Production. We specialize in providing high-quality anodes crafted with precision engineering and superior materials. Our products meet stringent industry standards and undergo comprehensive testing to ensure reliability and performance. We offer various standard and customized certifications, complete test reports, and support OEM requirements. With our commitment to quality, fast delivery, and excellent customer service, we aim to be your trusted partner in manganese dioxide production applications. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.