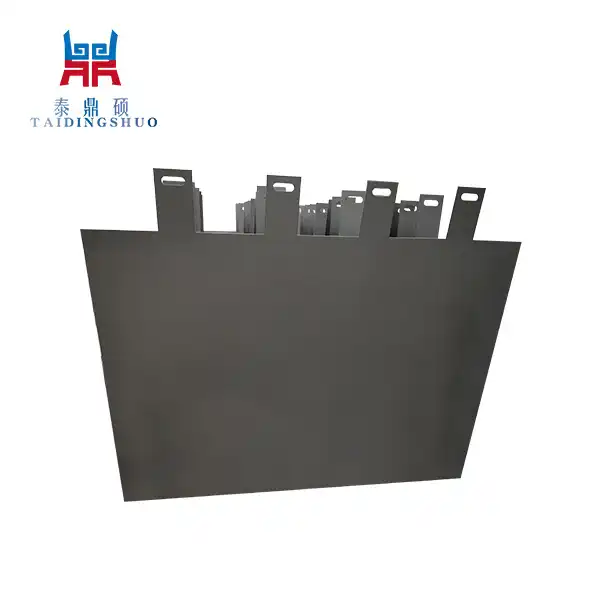

Product Description

Titanium anodes assume a vital part in the electroplating system for copper extraction, offering various benefits that add to the productivity, maintainability, and cost-viability of copper electroplating tasks. Through electroplating, a layer of copper is deposited on a substrate with an electric current to extract copper. It play a crucial role in making this process easier.

One of the essential elements of it in electroplating for copper extraction is their excellent erosion opposition. The electroplating system includes the utilization of destructive electrolytes and synthetics that can debase conventional anode materials over the long run. Titanium's high consumption obstruction guarantees the strength and life span of the anodes, permitting them to endure the unforgiving substance conditions and electrochemical responses associated with copper electroplating. This consumption obstruction is fundamental for keeping up with the presentation and productivity of the anodes all through the electroplating tasks.

In addition, it offer high conductivity, empowering productive electron move and electrochemical responses during the copper extraction process. The product serves as the site for oxidation reactions when copper ions are present in the electrolyte solution. This makes it easier for copper to be deposited on the substrate. In copper electroplating operations, increased productivity and resource utilization are made possible by titanium's high conductivity, which results in faster reaction rates and higher yields of copper deposition.

Moreover, they are practical and harmless to the ecosystem contrasted with different materials regularly utilized in electroplating processes. Electroplating facilities save money because they don't need to be replaced as often because of their durability and longevity. Additionally, because titanium is a sustainable and readily available material, it is an excellent choice for electroplating operations that place an emphasis on resource efficiency and sustainability.

In general, the use of it in electroplating to extract copper has revolutionized the industry by offering a dependable, cost-effective, and efficient method for depositing copper onto substrates. Titanium Anodes for Copper Electrodeposition are essential for optimizing electroplating processes, promoting resource recovery, and advancing the principles of sustainable manufacturing in the copper extraction industry due to their corrosion resistance, high conductivity, and sustainability. As the interest for great copper keeps on expanding, they are probably going to stay a critical innovation in streamlining copper electroplating tasks and meeting industry prerequisites.

Basic Product Details:

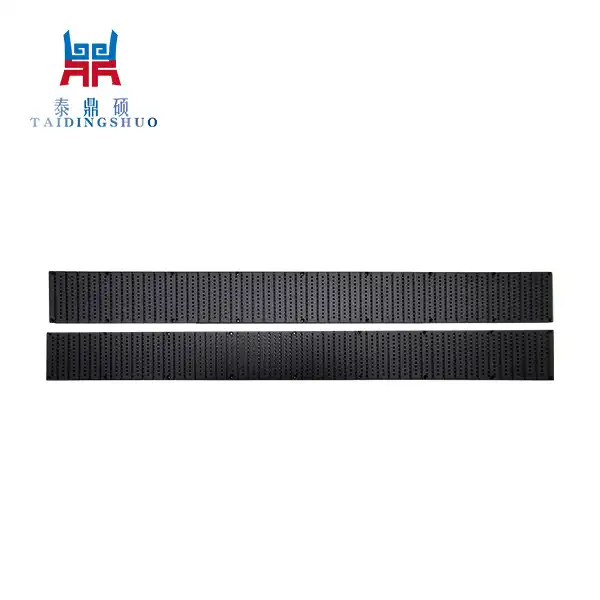

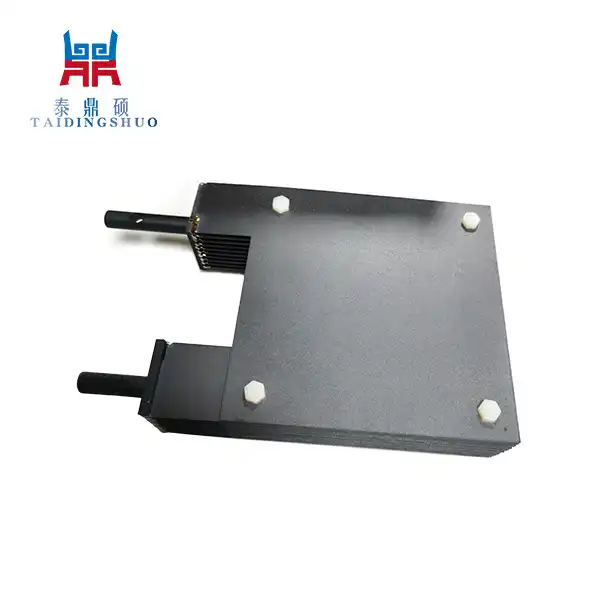

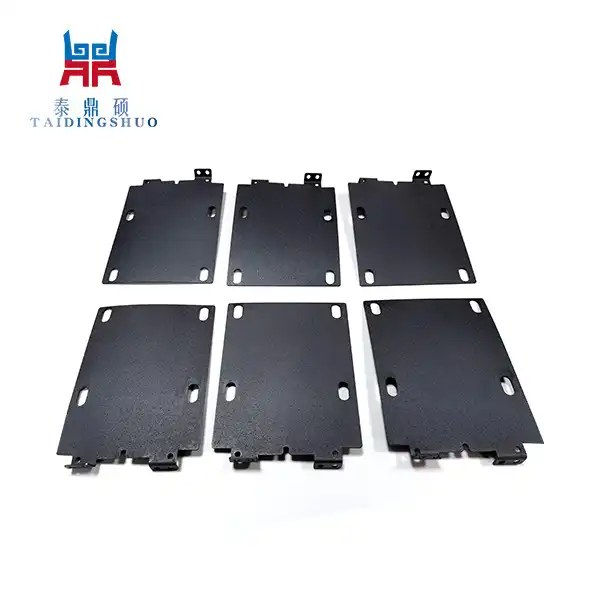

- Product Name: Titanium Anode for Electroplating Copper Extraction

- Manufacturer: Tai Ding Shuo Industrial Co., Ltd.

- Material: Titanium

- Certifications: ISO 9001:2015, RoHS Compliance

- Customization: Available upon request

- Contact: For inquiries and orders, email us at fujianuo@shelllaiqi.com

Product Standards:

| Parameter | Standard |

|---|---|

| Dimensions | Customizable |

| Coating Thickness | 10-30 microns |

| Current Density Range | 100-300 mA/cm² |

| pH Range | 1-12 |

| Temperature Range | Up to 80°C |

| Lifetime | 3,000-5,000 hours |

Product Attributes:

- High purity titanium substrate ensures corrosion resistance and durability.

- Uniform coating distribution for consistent performance.

- Optimized design for enhanced current distribution and efficiency.

- Superior adhesion of coating prevents delamination.

- Suitable for various electroplating environments.

Product Functions:

Titanium anodes are an essential component of the electroplating procedure for copper extraction because they provide a number of essential functions that are necessary for the operation's efficiency and effectiveness.

One of the essential elements of it in electroplating for copper extraction is their amazing erosion obstruction. The electroplating system includes the utilization of destructive electrolytes and synthetics that can debase conventional anode materials over the long run. Titanium's high consumption obstruction guarantees the strength and life span of the anodes, permitting them to endure the unforgiving substance conditions and electrochemical responses associated with copper electroplating. Throughout the electroplating process, the anodes' performance and efficiency must be maintained due to this resistance to corrosion.

Besides, it gives a steady and latent surface for the electrochemical responses that happen during copper extraction through electroplating. The product serves as the site for oxidation reactions when copper ions are present in the electrolyte solution. This makes it easier for copper to be deposited on the substrate. The steady and idle surface of titanium guarantees the immaculateness and nature of the copper stored, making it an optimal material for electroplating activities.

Also, it offers high conductivity, empowering productive electron move and electrochemical responses during the copper extraction process. In copper electroplating operations, increased productivity and resource utilization are made possible by titanium's high conductivity, which results in faster reaction rates and higher yields of copper deposition. The electroplating process is improved by this effective electron transfer, which results in increased copper deposition and decreased energy consumption.

In addition, when compared to other materials that are frequently utilized in electroplating procedures, they are economical as well as friendly to the environment. Electroplating facilities save money because they don't need to be replaced as often because of their durability and longevity. Furthermore, titanium is a feasible material, going with it a favored decision for electroplating tasks that focus on maintainability and asset productivity.

By and large, the elements of titanium anode stainless steel cathode copper plating in electroplating for copper extraction incorporate giving erosion opposition, filling in as the site for electrochemical responses, and empowering proficient electron move. These capabilities are fundamental for guaranteeing the solidness, productivity, and manageability of electroplating tasks, making it a basic part in the development of top notch copper through electroplating processes.

Features:

- Advanced titanium substrate for enhanced durability.

- Customizable dimensions to fit specific application requirements.

- Uniform coating distribution for consistent performance.

- Superior adhesion to substrate prevents premature failure.

- Wide operating parameters for versatility in various environments.

Advantages and Highlights:

- High-quality titanium material ensures long-term durability.

- Customization options available to meet unique specifications.

- Superior coating technology for enhanced performance and longevity.

- Cost-effective solution with minimized maintenance requirements.

- Expert engineering support and technical assistance provided.

Application Areas:

- Electroplating industry for copper extraction and deposition.

- Printed circuit board (PCB) manufacturing.

- Metal finishing and surface coating processes.

- Electronics manufacturing and semiconductor fabrication.

- Automotive and aerospace industries for corrosion protection.

OEM Services:

- Customized anode design and fabrication according to client specifications.

- Private labeling and branding options available.

- Flexible manufacturing capabilities to meet varying demands.

- Technical support for product integration and optimization.

- Fast turnaround times and reliable delivery services.

Certifications:

FAQs:

- For best performance, what is the recommended current density?

The prescribed current thickness goes from 100 to 300 Mama/cm², contingent upon the particular application prerequisites. - Is it possible to modify the product's dimensions?

Yes, we provide services for customizing the dimensions to meet your specific requirements. - What is the commonplace life expectancy of the product?

The typical lifespan is between 3,000 and 5,000 hours, depending on operating conditions and routine maintenance.

Material Properties and Details:

- Titanium: Known for its exceptional corrosion resistance, high strength-to-weight ratio, and biocompatibility.

- Coating Thickness: Typically 10-30 microns, ensuring adequate protection and conductivity.

- pH Range: Wide pH tolerance from 1 to 12, suitable for various electroplating solutions.

- Temperature Range: Operating temperature up to 80°C, enabling performance in diverse environments.

Tai Ding Shuo Industrial Co., Ltd., your trusted partner in electrochemical solutions, stands ready to meet your titanium anode stainless steel cathode copper plating needs. With our commitment to quality, reliability, and customer satisfaction, we offer a comprehensive range of standard and customized products, backed by industry-leading certifications and extensive testing. For inquiries or orders, contact us today at fujianguo@shelllaiqi.com. Let us empower your electroplating processes with our superior it solutions.