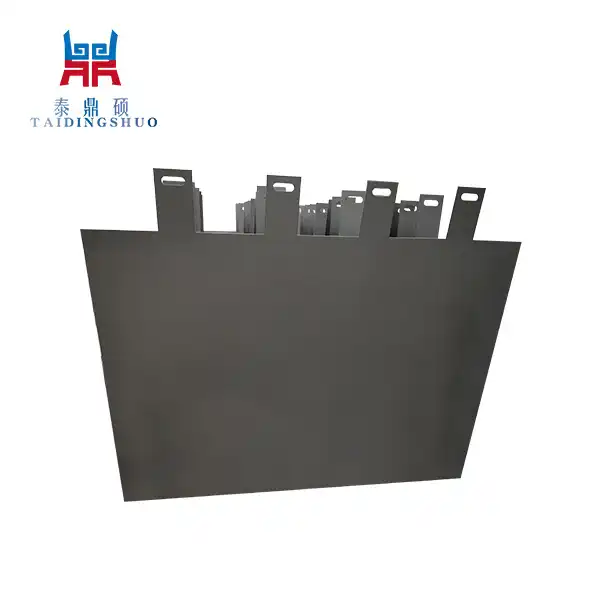

Product Description

Titanium anodes are generally used in the electrolytic extraction of metals from sulfate arrangements, offering various benefits that settle on them a favored decision for this application. It play a crucial role in facilitating the electrochemical reactions that transform metal ions in sulfate solutions into pure metal deposits during the electrolytic extraction of metals from sulfate solutions.

The exceptional resistance to corrosion of it is one of the primary advantages of using them in this process. Despite the fact that sulfate solutions can be corrosive, it have remarkable durability and are able to withstand the abrasive chemical environment without deteriorating over time. In metal extraction processes, its reliability and longevity are guaranteed by their resistance to corrosion.

Additionally, the high electrical conductivity of it makes it possible for fast electron transfer during electrolysis. Metal extraction from sulfate solutions can now be done more effectively and at a faster rate thanks to the rapid deposition of metal ions onto the cathode.

When it comes to electrolytically extracting metals from sulfate solutions, titanium anodes have a number of advantages, one of which is their capacity to function at high current densities. Industrial metal extraction and processing of large volumes of sulfate solution are made possible by this feature. It can be effectively increased to satisfy the needs of enormous scope metal extraction processes.

Additionally, specific requirements for metal extraction from sulfate solutions can be met by customizing it. They can be covered with different materials to work on their presentation or custom-made with explicit calculations to advance the electrochemical cycle. The optimization of metal extraction procedures for various metals and sulfate solutions is made possible by this adaptability.

In rundown, titanium anodes are fundamental parts in the electrolytic extraction of metals from sulfate arrangements because of their consumption obstruction, high conductivity, capacity to work at high current densities, and customization choices. As the interest for practical and proficient metal extraction strategies keeps on rising, it are ready to assume a urgent part in the extraction of metals from sulfate arrangements in different modern applications.

Product Standards:

- Compliant with international quality standards

- Rigorously tested for reliability and performance

Basic Parameters:

- Material: Titanium

- Coating: IrO2, RuO2, Pt, etc.

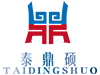

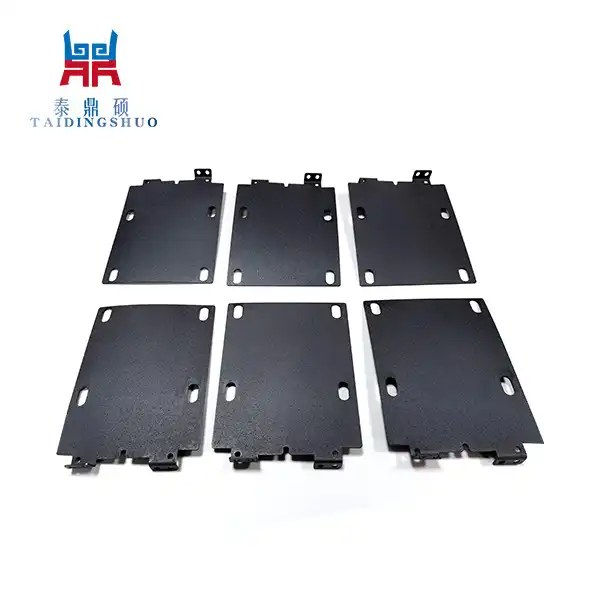

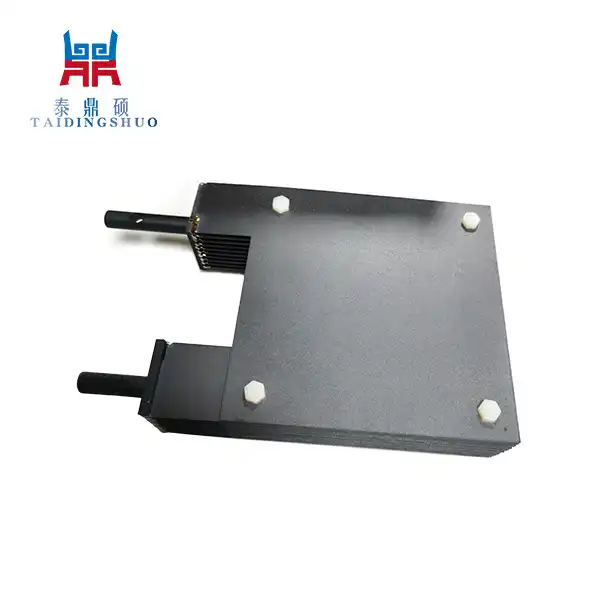

- Shape: Plate, mesh, tube, etc.

- Size: Customizable to suit specific requirements

Product Functions:

In the electrolytic extraction of metals from sulfate solutions, Electrolytic Metal Extraction Titanium Anodes play a crucial role. Here are the essential elements of it in this cycle:

- Sulfate ion oxidation:The oxidation of sulfate ions (SO42-) in the electrolyte solution is made easier by it. The electrolysis process produces the oxygen gas as a byproduct, and the protons contribute to the solution's acidity.

- Current Appropriation:It ensure that the electrolytic cell receives the same amount of current throughout. This is significant for effective metal extraction and to forestall restricted over-oxidation or under-extraction. Its effective current distribution capabilities are made possible by their high electrical conductivity and low oxygen evolution.

- Electrocatalytic Movement:In sulfate solutions,it exhibit electrocatalytic activity toward the oxidation of specific metal ions. By lowering the overpotential required for metal deposition, this electrocatalytic effect improves the efficiency of metal extraction.

- Protection from Corrosion:It are exceptionally impervious to consumption in sulfate arrangements. The development of a defensive oxide layer on the titanium surface forestalls further erosion and guarantees long haul steadiness of the anode. This consumption obstruction is urgent for keeping up with the trustworthiness and execution of the anode overstretched times of activity.

- Control of Oxygen Evolution:At the anode surface, oxygen gas evolution is controlled by it. The formation of persulfate ions (S2O82-), which can hinder metal extraction and reduce current efficiency, is minimized by titanium's low oxygen evolution potential.

Generally,it exceptionally compelling and tough cathode materials for the electrolytic extraction of metals from sulfate arrangements. They are excellent candidates for this strenuous industrial process due to their distinctive properties and adaptability.

Features:

- Enhanced durability

- Optimal electrochemical performance

- Customizable design options

- Wide applicability

Advantages and Highlights:

- Superior corrosion resistance ensures prolonged lifespan

- High conductivity guarantees efficient electrolytic processes

- Customizable design caters to diverse industrial needs

- Enhanced electrochemical performance for superior metal extraction

Application Areas:

- Chemical processing

- Electroplating

- Metal refining

- Environmental remediation industries

OEM Services:

We offer comprehensive OEM services, allowing clients to customize anodic coating titanium to their precise specifications. Our experienced team ensures seamless integration of OEM requirements, delivering tailored solutions that meet the unique needs of each customer.

Certifications:

FAQs:

-

What is the lifespan of your product?

-

Our anodes are designed for long-term durability, with a lifespan that varies depending on operating conditions and maintenance practices.

-

Can you customize the design of the anodes?

-

Yes, we offer customizable design options to meet the specific requirements of our clients.

-

Are your products compliant with industry standards?

-

Yes, our product adhere to stringent quality standards to ensure reliability and performance.

Material Properties and Details:

- Titanium: Known for its exceptional corrosion resistance and mechanical strength, titanium serves as the ideal material for electrolytic applications.

- Coatings (IrO2, RuO2, Pt, etc.): These coatings enhance the electrochemical properties of the anode, ensuring optimal performance in sulfate solution environments.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a reputable manufacturer and supplier of anodic coating titanium for Electrolytic Extraction of Metals from Sulfate Solution. Our commitment to quality and innovation has positioned us as a leader in the industry.

Our Services:

- Various standard and customized certifications

- Complete test reports for quality assurance

- OEM support for tailored solutions

- Fast delivery

- Secure packaging to ensure product integrity

- Expert technical support and consultation

For inquiries or to order your product for electrolytic extraction needs, please contact us at fujianguo@shelllaiqi.com. Trust Tai Ding Shuo Industrial Co., Ltd. for reliable solutions that meet your industrial requirements.