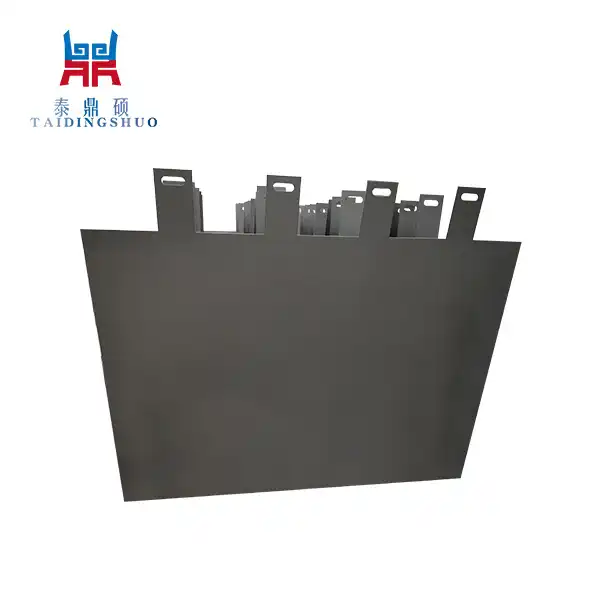

Titanium anode for electrolytic extraction of metals from chloride-sulfate mixed solution

Comprehensive test reports for quality assurance

OEM support for tailored solutions

Fast delivery and secure packaging

Dedicated customer service and technical support

Product Description

Titanium anodes stand out enough to be noticed in the field of electrolytic extraction of metals from chloride-sulfate blended arrangements because of their phenomenal consumption obstruction, high proficiency, and cost-adequacy. An electrolytic cell's positive electrode is a product, and metal ions are selectively extracted from the solution and deposited on the cathode in this procedure.

Its resistance to corrosion, even in harsh chemical environments, is one of the process's main advantages. Because of this, the anode can last for a longer time, requiring fewer frequent repairs and replacements. Moreover, it have a high current proficiency, and that implies that a more noteworthy measure of metal can be removed from the arrangement with less energy utilization.

The capacity of it to work at high temperatures and tensions, making them reasonable for a great many modern applications, is one more benefit of involving them in the electrolytic extraction of metals. Due to this versatility, many different metals can be extracted from chloride-sulfate mixed solutions with high yield and purity, including copper, nickel, and zinc.

Moreover, titanium anodes are savvy contrasted with different materials usually utilized in electrolytic extraction processes, like platinum or lead. Their lower starting expense and longer life expectancy make them a more manageable choice for modern applications, adding to both monetary and natural advantages.

All in all, It offer a dependable and productive answer for the electrolytic extraction of metals from chloride-sulfate blended arrangements. They are an excellent option for businesses looking to enhance their metal extraction procedures because of their resistance to corrosion, high current efficiency, and affordability. In the field of electrolytic metal extraction, titanium anodes are anticipated to play an increasingly significant role as technology and research continue to advance.

Product Standards:

- Compliance with ASTM B265 standards

- Customizable to meet specific industry requirements

Basic Parameters:

| Parameter | Value |

|---|---|

| Material | Titanium |

| Coating Material | Mixed Metal Oxides (MMO) |

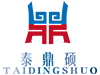

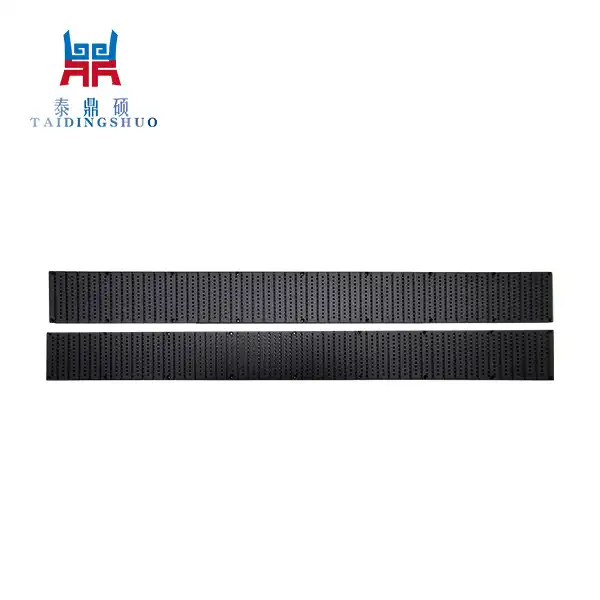

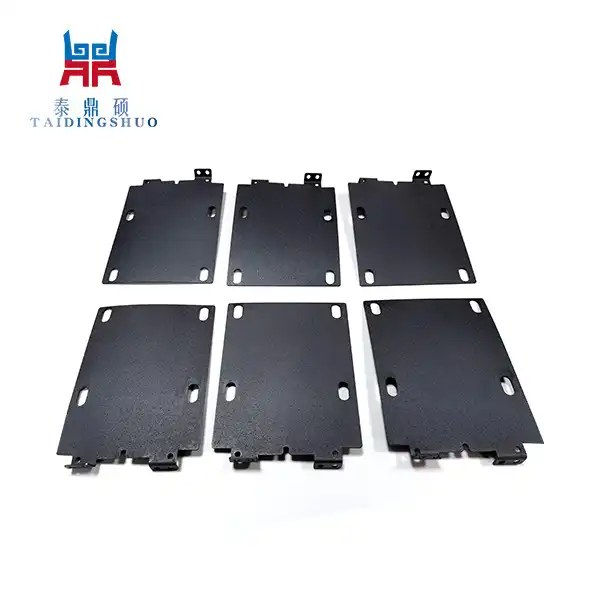

| Shape | Sheet, Mesh, or Customized Designs |

| Coating Thickness | 10-20 microns |

| Current Density | Up to 2000 A/m² |

| Temperature Range | Up to 80°C |

| pH Range | 1-13 |

Product Attributes:

- Corrosion resistance

- High conductivity

- Long lifespan

- Superior efficiency

- Customizable designs

Product Functions:

In the electrolytic extraction of metals from chloride-sulfate blended arrangements, Titanium Anodes for Electrolysis of Chloride-Sulfate Mixed Solutions assume an essential part. These anodes are designed to make it simpler to selectively deposit metal ions on the cathode, allowing for efficient and high-purity metal extraction. Coming up next are a few significant jobs that titanium anodes play in this cycle:

- Guarding Against Corrosion: It are significantly impenetrable to utilization, even in powerful manufactured conditions, for instance, chloride-sulfate mixed game plans. This property ensures the anode's strength and longevity, reducing the need for routine maintenance and replacement.

- High Availability of Current: Due to their high current efficiency, it can effectively facilitate the transfer of metal ions from the solution to the cathode. As a result, the cycle is more practical and productive, with a higher extraction yield and lower energy consumption.

- Metal Testimony Specific: Considering the high purity of metal extraction, they are designed to specifically store specific metal particles on the cathode. This selectivity is essential in industries where the extracted metal's quality is of the utmost importance.

- Working Conditions: Due to their ability to withstand high temperatures and pressures, they are suitable for a wide range of industrial applications. Different metals can be extracted from chloride-sulfate mixed solutions under a variety of operating conditions because of this adaptability.

- Cost-Effectiveness: It are less expensive than those made of platinum or lead, two materials that are frequently utilized in electrolytic extraction processes. They are an affordable and wise choice for modern applications due to their longer life expectancy and lower initial cost.

- Benefits for the environment: When metals are extracted by electrolysis from chloride-sulfate-mixed arrangements, the use of it can improve natural manageability. Due to their durability and effectiveness, the extraction process's overall energy consumption and waste generation are reduced.

In frame, Titanium Anodes for Electrolysis of Chloride-Sulfate Mixed Solutions serve various abilities in the electrolytic extraction of metals from chloride-sulfate mixed courses of action, including utilization resistance, high current efficiency, specific metal declaration, versatility in working conditions, cost-ampleness, and regular benefits. Because of their remarkable properties, they play a crucial role in businesses' efforts to improve the efficiency and upkeep of their metal extraction processes.

Features:

- Advanced MMO coating for enhanced durability

- Tailored designs for specific electrolysis applications

- Consistent performance over a wide range of operating conditions

- Easy installation and maintenance

Advantages and Highlights:

- High corrosion resistance extends service life

- Efficient metal extraction improves process economics

- Customization options for diverse industrial needs

- Environmentally friendly alternative to traditional methods

Application Areas:

- Mining and metallurgy

- Electroplating

- Chemical synthesis

- Water treatment

- Metal recycling

OEM Services:

Customers can tailor anode designs, dimensions, and coatings to meet their specific requirements through our comprehensive OEM services. Our skilled engineers collaborate closely with clients to create individualized solutions that maximize performance and profitability.

Certifications:

FAQs:

-

What is the typical lifespan of your product?

-

Our anodes are designed for long-term use, with lifespans exceeding 5 years under normal operating conditions.

-

Can you provide installation assistance?

-

Yes, we offer installation guidance and technical support to ensure optimal performance.

-

Are your anodes compatible with different electrolyte compositions?

-

Yes, our anodes can be customized to suit various electrolyte solutions and operating parameters.

Material Properties and Details:

The Titanium substrate provides excellent corrosion resistance, even in aggressive environments. The mixed metal oxide (MMO) coating enhances conductivity and durability, ensuring stable performance over extended periods. This combination of materials allows our anodes to withstand harsh conditions and maintain efficiency throughout their lifespan.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a reputable manufacturer and supplier of anodic oxide coating titanium for electrolytic extraction applications. We adhere to stringent quality standards and offer various certifications and test reports to guarantee product reliability. Our OEM services enable clients to tailor solutions to their exact specifications, while our fast delivery and attentive customer support ensure a seamless experience. For inquiries or orders, please contact us at fujianguo@shelllaiqi.com.

With our anodic oxide coating titanium, customers can achieve superior metal extraction performance while minimizing environmental impact. Partner with Tai Ding Shuo Industrial Co., Ltd. for innovative solutions and exceptional service.