Product Description

Titanium anodes have turned into a crucial part during the time spent reusing waste batteries, offering various benefits that add to the proficiency, supportability, and cost-viability of battery reusing tasks. Squander batteries contain important materials like lead, lithium, and different metals that can be recuperated and reused through reusing processes. It assume a urgent part in working with these cycles by giving a dependable and viable method for extricating and recuperating these important materials from squander batteries.

Its capacity to withstand the challenging chemical environments and electrochemical reactions involved in the recycling of waste batteries is one of their primary functions. Squander batteries contain destructive materials and electrolytes that can debase conventional anode materials after some time. The anodes can continue to function effectively and efficiently throughout the recycling process thanks to titanium's exceptional resistance to corrosion.

In addition, the high conductivity of it makes it possible for effective electrochemical reactions to take place during the recycling of old batteries. At the point when an electric flow is applied to the electrolyte arrangement containing waste battery materials, the product fills in as the site for oxidation responses, working with the extraction and recuperation of significant metals like lead and lithium. The high conductivity of titanium advances quicker response rates and more significant returns of metal recuperation, prompting expanded efficiency and asset usage in the reusing system.

Also, titanium anodes are practical contrasted with different materials usually utilized in battery reusing tasks. Recycling facilities save money because they don't need to be replaced as often because of their durability and longevity. Additionally, titanium is sustainable and readily available, making it an environmentally friendly option for waste battery recycling operations that place an emphasis on resource efficiency and sustainability.

In general, the introduction of Waste Battery Recycling Titanium Anodes into the recycling of used batteries has revolutionized the industry by offering a dependable, cost-effective, and effective method for obtaining useful materials from used batteries. In the battery recycling industry,it play a crucial role in optimizing recycling procedures, promoting resource recovery, and advancing the principles of the circular economy due to their sustainability, high conductivity, and resistance to corrosion.

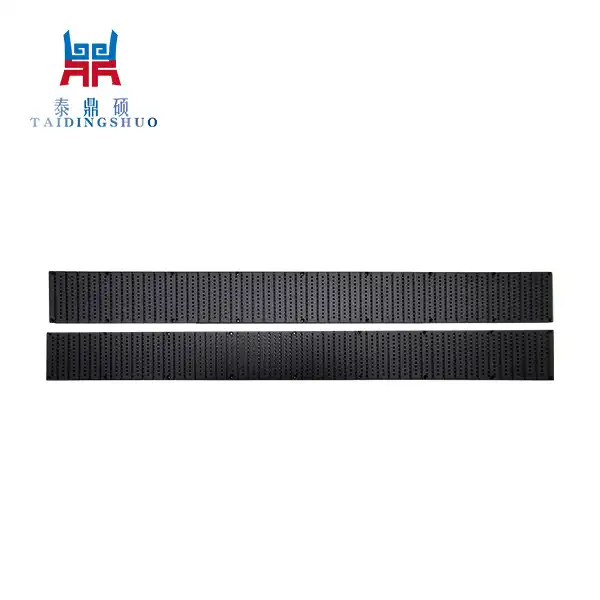

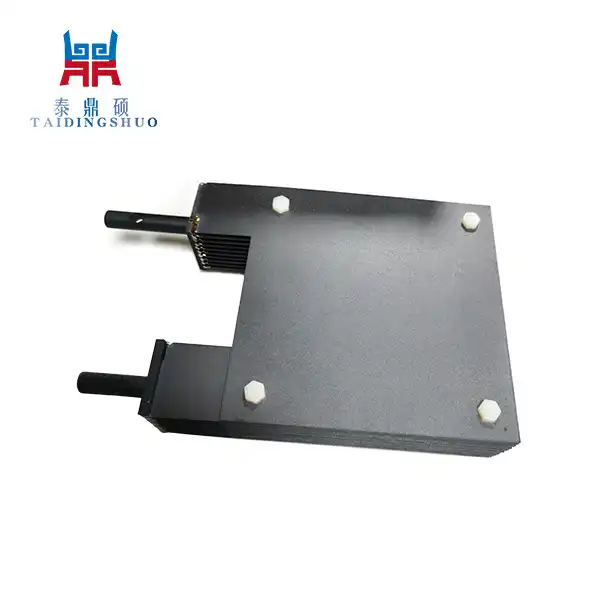

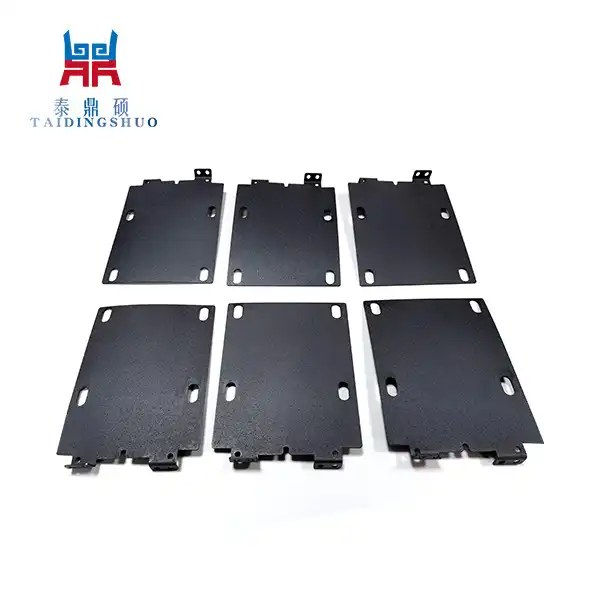

Product Details:

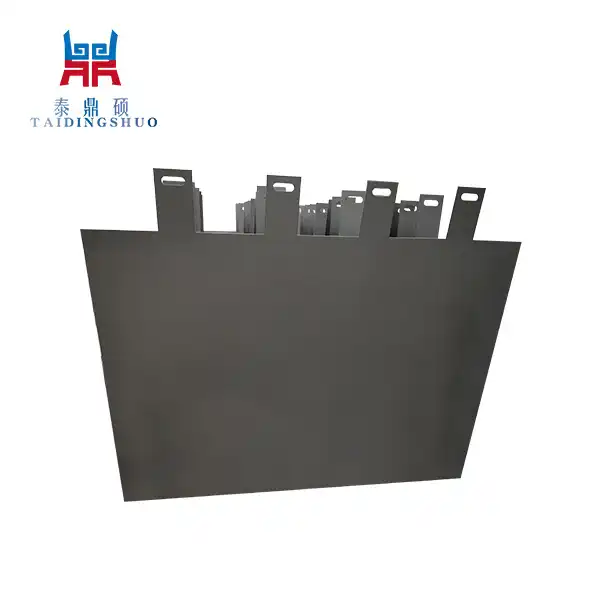

Our product for waste battery recycling is meticulously crafted using high-grade titanium material, ensuring durability and longevity in harsh recycling environments. It is engineered with precision to meet the exacting standards of the recycling industry, providing consistent and reliable performance.

Product Standards:

- Material Coating in Titanium: Blended metal oxide (MMO)

- Aspects Current Density that Can Be Changed: Up to 2000 A/m²

- Working Temperature and Lifetime: Up to 80°C 5 to 10 years (depending on conditions of operation)

Product Attributes:

- Corrosion resistance

- High current efficiency

- Long service life

- Low maintenance requirements

- Superior mechanical strength

- Excellent conductivity

Product Functions:

Titanium anodes play a crucial role in the recycling of used batteries because they provide a number of important benefits that improve recycling operations' efficiency, effectiveness, and sustainability.

Because of their exceptional resistance to corrosion, it play a crucial role in the recycling of used batteries. Electrolytes and materials in waste batteries can corrode traditional anode materials over time. The anodes are able to withstand the harsh chemical environments and electrochemical reactions that are involved in the recycling process thanks to titanium's high corrosion resistance, which ensures their durability and longevity. This consumption opposition is fundamental for keeping up with the presentation and proficiency of the anodes all through the reusing tasks.

Moreover, it give a steady and latent surface for the electrochemical responses that happen during waste battery reusing. At the point when an electric flow is applied to the electrolyte arrangement containing waste battery materials, the product fills in as the site for oxidation responses, working with the extraction and recuperation of important metals like lead, lithium, and different metals present in the batteries. The steady and inactive surface of titanium guarantees the virtue and nature of the recuperated metals, making it an optimal material for reusing activities.

Also, it offer high conductivity, empowering productive electron move and electrochemical responses during the reusing system. Titanium's high conductivity results in faster reaction rates and higher metal recovery yields, increasing waste battery recycling operations' overall productivity and resource utilization. The recycling process is improved by this effective electron transfer, which results in increased metal recovery and decreased energy consumption.

In general, customized titanium anode are used in waste battery recycling to prevent corrosion, facilitate electrochemical reactions, and facilitate efficient electron transfer. These capabilities are fundamental for guaranteeing the sturdiness, effectiveness, and supportability of reusing tasks, making it a basic part in the recuperation of significant materials from squander batteries. In the waste battery recycling industry, they are likely to play an increasingly significant role in advancing the circular economy principles as demand for sustainable recycling practices continues to rise.

Features:

- Advanced MMO coating for enhanced performance

- Customizable dimensions to fit various recycling setups

- Robust construction for reliable operation in demanding environments

- Compatible with various electrolytes and operating conditions

Advantages and Highlights:

- Further develops process effectiveness and efficiency

- Supports asset recuperation

- Adds to maintainable assembling rehearses by making battery reusing all the more harmless to the ecosystem

- Sets aside cash over the long haul thanks to a lengthy help life.

Application Areas:

- Battery recycling plants

- Metal recovery facilities

- Environmental remediation projects

- Research and development laboratories

OEM Services:

At Tai Ding Shuo Industrial Co., Ltd., we understand that every recycling operation is unique. That's why we offer comprehensive OEM services, allowing our customers to customize our product to their specific requirements. From tailored dimensions to specialized coatings, we work closely with our clients to deliver solutions that optimize their recycling processes.

Certifications:

FAQs:

Q: What types of batteries can be recycled using your product? A: Our product is suitable for recycling various types of batteries, including lead-acid, nickel-cadmium, and nickel-metal hydride batteries.

Q: How long does your product typically last in a recycling application? A: The lifespan of our product can vary depending on factors such as operating conditions and maintenance practices, but it typically ranges from 5 to 10 years.

Q: Can your customized titanium anode be used in both batch and continuous recycling processes? A: Yes, our product is versatile and can be integrated into both batch and continuous recycling systems, offering flexibility to suit different processing requirements.

Tai Ding Shuo Industrial Co., Ltd.:

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of Waste Battery Recycling Titanium Anodes for waste battery recycling applications. We are committed to providing our customers with top-quality products that meet the highest industry standards. Our They are backed by various certifications and comprehensive test reports, ensuring their performance and reliability.

In addition to our standard product offerings, we also offer OEM services to accommodate the unique needs of our customers. With fast delivery, tight packaging, and dedicated customer support, we strive to exceed our clients' expectations at every step of the process.

For more information or to inquire about our product for waste battery recycling, please contact us at fujianguo@shelllaiqi.com. Choose Tai Ding Shuo Industrial Co., Ltd. for superior quality and service in battery recycling solutions.