Product Description

Due to their high efficiency, high cost-effectiveness, and excellent resistance to corrosion, titanium anodes are frequently utilized in the nickel electrodeposition process. A product in an electrolytic cell acts as the positive electrode during this procedure, making it easier for nickel to be deposited on the substrate. For the production of high-quality nickel coatings with a variety of uses, this method is frequently utilized in aerospace, automotive, and electronics industries.

One of the vital benefits of involving it in the electrodeposition of nickel is their outstanding consumption opposition. Nickel plating processes frequently include brutal substance conditions, and it can endure these circumstances, guaranteeing a more extended life expectancy and lessening the requirement for continuous substitutions. This strength adds to cost reserve funds and functional proficiency in modern applications.

Moreover, titanium anodes offer high current proficiency, meaning they can actually move nickel particles from the electrolyte answer for the substrate. This outcomes in a more effective testimony process, with a higher statement rate and further developed covering quality. The utilization of it can assist accomplish uniform and smooth nickel coatings with phenomenal grip properties.

They are not only highly efficient and resistant to corrosion, but they are also less expensive than alternatives made of platinum or lead. It is a long-term option for businesses looking to optimize their electrodeposition processes while lowering overall costs due to their lower initial cost and longer operational lifespan.

Additionally,they are flexible and can be utilized in an assortment of electrolytic nickel plating applications, including embellishing, practical, and modern coatings. They can work at various temperatures and current densities, considering adaptability in process boundaries to meet explicit covering prerequisites.

In conclusion, products are an essential component in the nickel electrodeposition process because they are resistant to corrosion, efficient, cost-effective, and versatile in a wide range of industrial applications. Their remarkable properties pursue them a favored decision for businesses looking to accomplish excellent nickel coatings with ideal execution and sturdiness. As exploration and innovation keep on propelling, they are supposed to stay a critical part in the electrodeposition of nickel processes.

Product Basics

| Attribute | Details |

|---|---|

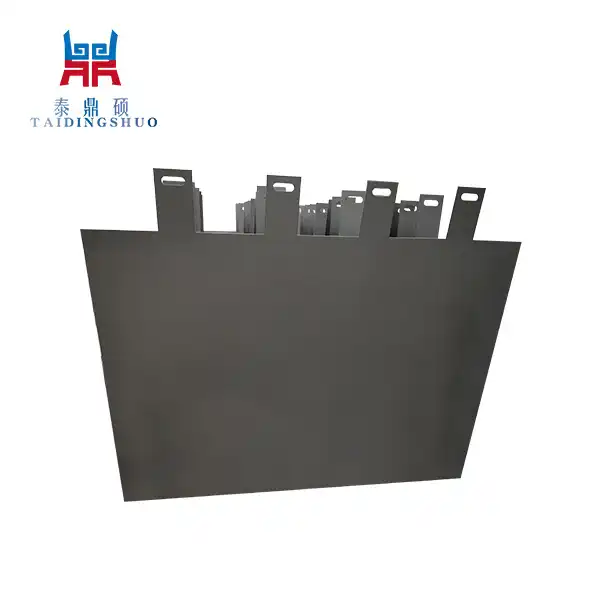

| Product Name | Titanium Anode for Electrodeposition of Nickel |

| Material | Titanium |

| Coating Material | Mixed Metal Oxide (MMO) |

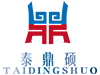

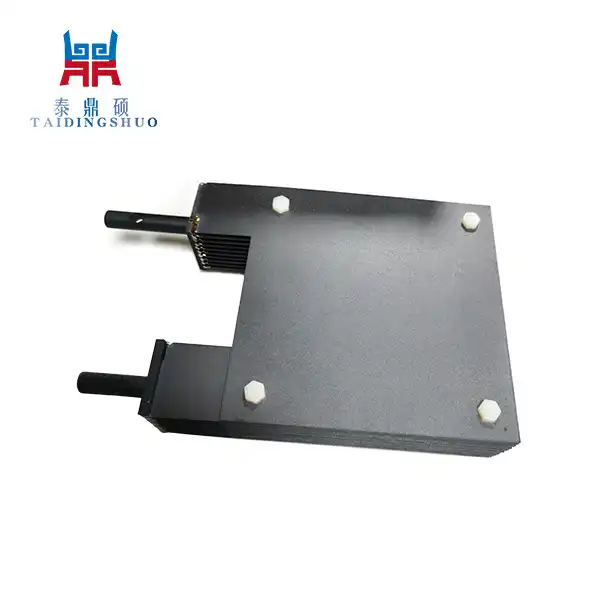

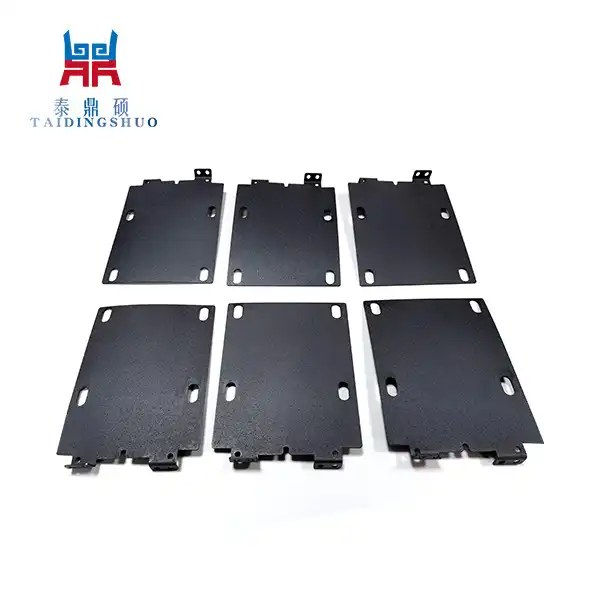

| Shape | Plate, Mesh, Tube, Ribbon |

| Size | Customizable |

| Coating Thickness | 5-30 microns |

| Connection | Threaded, Flanged, Welded |

| Working Temperature | Up to 80°C |

| Current Density | 100-300 mA/cm² |

| Lifetime | 3-5 years |

Product Standards

- ASTM B265

- ASTM B348

- ASTM B338

- ASTM B381

Product Attributes

- High corrosion resistance

- Superior conductivity

- Uniform current distribution

- Long service life

- Customizable sizes and shapes

- Stable performance under high temperatures

- Environmentally friendly

Product Functions

Titanium Anodes for Electroplating Nickel are necessary for the nickel electrodeposition process because they carry out a number of essential tasks that boost the process's effectiveness and efficiency. The essential elements of it in the nickel electrodeposition are as per the following:

- Guarding Against Corrosion: Due to their high resistance to corrosion, they are ideal for use in the harsh chemical environments that nickel electrodeposition typically encounters. This utilization resistance ensures the life expectancy and strength of the anode, diminishing upkeep necessities and ensuring unsurprising execution after some time.

- High Availability of Current: It shows high current efficiency, meaning they can effectively move nickel particles from the electrolyte reply for the substrate being plated. With a faster deposition rate and improved coating quality, the electrodeposition procedure is more productive and cost-effective as a result of this high efficiency.

- Deposition Equal: It ensures a uniform coating thickness by assisting in the uniform nickel deposition onto the substrate. For excellent nickel coatings with desirable properties like consumption resistance, wear obstruction, and stylish allure, this consistency is essential.

- Cost-Effectiveness: They are a more cost-effective option for nickel electrodeposition than other materials like platinum. They are a practical and savvy decision for modern applications that require nickel plating due to their more extended functional life expectancy and lower introductory expense.

- Versatility: It can be used in a wide range of nickel plating electrodeposition procedures, including industrial, decorative, and functional ones, thanks to their adaptability. They can actually function under a variety of temperature and current thickness conditions, allowing process boundaries to be tailored to specific covering requirements.

- Benefits for the environment: Utilizing it for nickel electrodeposition is beneficial to the environment because it reduces the amount of energy consumed and waste produced during the plating process. Their productivity and durability contribute to a nickel plating activity that is easier to manage and harmless to the ecosystem.

In conclusion, nickel electrodeposition relies heavily on it because of their corrosion resistance, efficiency at high currents, uniform deposition, cost-effectiveness, versatility, and environmental benefits. Their fascinating properties seek after them a leaned toward choice for adventures hoping to achieve brilliant nickel coatings capably and effectively. As development continues to drive, anodic titanium oxide should remain a basic part in the electrodeposition of nickel processes.

Features

- Corrosion Resistance: The titanium substrate combined with MMO coating offers exceptional resistance to corrosive environments, ensuring longevity and reliability.

- Uniform Deposition: Even current distribution across the anode surface guarantees uniform nickel deposition, minimizing defects and ensuring consistent coating thickness.

- Customization: Available in various shapes, sizes, and connection types, allowing for tailored solutions to specific electrodeposition requirements.

- High Conductivity: Enhanced conductivity facilitates efficient electroplating processes, optimizing production efficiency.

- Temperature Stability: Capable of withstanding temperatures up to 80°C, ensuring stable performance in demanding electroplating applications.

Advantages and Highlights

- Enhanced corrosion resistance compared to traditional anode materials.

- Lower operating costs due to extended service life and reduced maintenance.

- Improved product quality with uniform nickel deposition.

- Versatile applications across industries such as automotive, electronics, and aerospace.

Application Areas

- Electroplating industry

- Automotive manufacturing

- Electronics production

- Aerospace engineering

- Metal finishing processes

OEM Services

We offer comprehensive OEM services, including custom design, manufacturing, and branding options tailored to meet individual customer requirements.

Certifications:

FAQs

Q: For nickel electrodeposition, how long do the product typically last?

A: Depending on operating conditions and care, it can last three to five years.

Q: Could the size and state of the anode at any point be modified?

A: Indeed, we offer customization choices for size, shape, and association type to suit explicit application necessities.

Q: For best performance, what is the recommended current density?

A: Depending on the electroplating process, the recommended current density typically ranges from 100 to 300 mA/cm2.

Material Properties and Details

For electrodeposition applications, titanium is the ideal substrate material due to its superior resistance to corrosion and high strength-to-weight ratio. The blended metal oxide (MMO) covering upgrades the anode's conductivity and gives predominant erosion obstruction, guaranteeing solid execution in brutal conditions.

About Tai Ding Shuo Industrial Co., Ltd.

Tai Ding Shuo Industrial Co., Ltd. is a leading manufacturer and supplier of anodic titanium oxide for electrodeposition of nickel. We adhere to strict quality standards and offer various standard and customized certifications, including ASTM B265, ASTM B348, ASTM B338, and ASTM B381. Our products undergo rigorous testing and come with complete test reports to ensure optimal performance and reliability. We provide fast delivery, secure packaging, and comprehensive OEM support. For inquiries or to order it for nickel electrodeposition, please contact us at fujianguo@shelllaiqi.com.